Compound nanofibers and thin films generate great interest in the academic and industrial community. Nanofibers with novel secondary structures (hollow, core-shell and porous) have extensive applications in biomedical fields, energy and environmental engineering areas. Their very large surface area to volume ratio, flexibility in surface functionalities, and superior mechanical performance (e.g. stiffness and tensile strength) make them a very active research topic.

Compound nanofibers and thin films generate great interest in the academic and industrial community. Nanofibers with novel secondary structures (hollow, core-shell and porous) have extensive applications in biomedical fields, energy and environmental engineering areas. Their very large surface area to volume ratio, flexibility in surface functionalities, and superior mechanical performance (e.g. stiffness and tensile strength) make them a very active research topic.

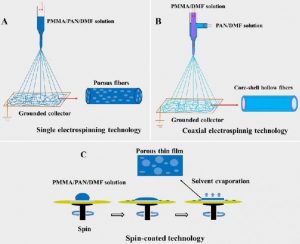

Recently, a joint team led by Prof. Xiangfang Peng (South China University of Technology) and Prof. Zhanhu Guo (University of Tennessee, Knoxville) demonstrated a comprehensive investigation focusing on the change of physical/chemical properties based on different morphologies. In this study, the same plastic precursors (polyacrylonitrile (PAN) and polymethyl-methacrylate (PMMA)) were processed into porous fibers, core-shell hollow fibers and porous thin films by coaxial, single electrospinning and spin-coated technologies, respectively. Different structures of the samples lead to different crystalline properties. When the amorphous PMMA was added into the hemicrystalline PAN matrix, the PMMA behaved as the nucleating agent to improve the growing of PAN crystals. Further, PMMA caused different types of crystals in the PAN matrix. These different morphologies and changes of crystalline properties affected the thermal properties of the materials. In addition, lower weight loss, higher degradation temperature and glass-transition temperatures of porous thin films were obtained, compared to those of porous fibers and core-shell hollow fibers. This work provides a better understanding on the relationship between the morphologies and the physical/chemical properties in plastic processing.