Diamonds have always been always popular particularly as a big and of a brilliant surface. They are renowned as a material with superlative physical qualities, most of which originates from the strong covalent bonding between atoms. In particular, diamond has the highest hardness and thermal conductivity of any bulk material.

However, the bigger the rough diamond, the bigger the risk of destroying it during cutting. Lasers have been used for sawing, kerfing, bruting and shaping of diamonds since the early 1990s. Diamond cutting is the art, and increasingly the science, of producing a faceted gem from a rough stone.

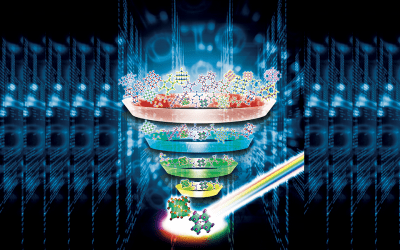

After analysing and scanning the raw gem, a laser is used to perform the computerised cut. The function of the laser lamp is to pump energy into the laser rod, the output is then amplified in the laser resonator to produce a coherent laser beam.

For diamond cutting, discharge lamps so called continuous wave lamps are the preferred option because they are ideal for high beam quality and a seamless, high-quality cut. Heraeus Noblelight has started to serve the global diamond processing industry since its origin and until today is the market leader in this field.

The company expained that they reached this position as these lamps produced in Cambridge, UK, are reliable and of high quality. This helps to minimise weight loss and breakage. A decisive fact while working with the hardest and last not least very expensive material.