In the body, native tissues, such as bone and skin, exhibit distinct, regional variations in their structures. The fabrication of multiphasic and multimodal scaffolds to mimic native tissue is important to deliver personalized medicines in the future. Melt electrowriting (MEW) could be instrumental in the production of such scaffolds, however this technology requires more intuitive design capabilities for biomedical engineers.

In their paper in Small, Professor Paul D. Dalton and colleagues from the University Hospital of Würzburg, and their co-worker from Queensland University of Technology, demonstrate controlled printing of fibers with different diameters as a new design approach for the fabrication of scaffolds for biomedical applications.

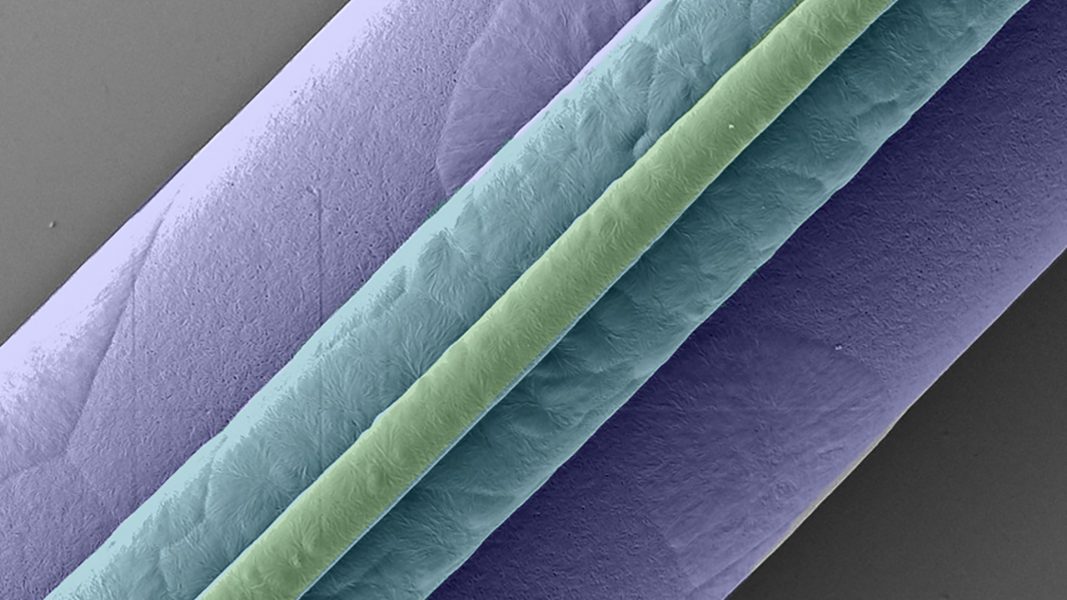

Optimization of the pressure and collector translation speed enabled the production of fibers with diameters from 2 to 50 µm. “On-the-fly” printing facilitated the production of multiphasic scaffolds with various fiber diameters in distinct regions, which were made in a single print using a single nozzle.

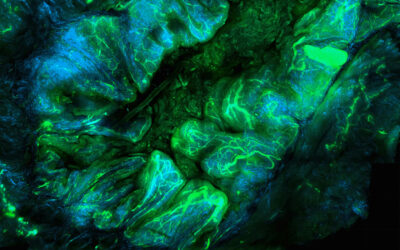

Multimodal scaffolds with a gradient of fiber diameters were also produced. “Catching fibers” were introduced into this scaffold and were effective in preventing cell spheroids from falling through the scaffold boxes.

The multiphasic scaffolds supported the growth of human mesenchymal stromal cells, where the cells adhered and proliferated through the scaffold.

The multimodal scaffolds effectively retained human adipose-derived stem cell spheroids, which could be further cultured within the scaffold.

To find out more about melt electrowriting and the production of these complex scaffolds, please visit the Small homepage.