Electric-powered and hybrid cars are key technologies for a more sustainable future, without reliance on fossil fuels. For electric vehicles, batteries that can deliver high power, high capacity and ultra-long durability are a necessity. Towards such automotive applications, researchers in Singapore have demonstrated a high-performance Li-battery with excellent efficiency, and an impressive 70% capacity retention over 4000 cycles.

Electric-powered and hybrid cars are key technologies for a more sustainable future, without reliance on fossil fuels. For electric vehicles, batteries that can deliver high power, high capacity and ultra-long durability are a necessity. Towards such automotive applications, researchers in Singapore have demonstrated a high-performance Li-battery with excellent efficiency, and an impressive 70% capacity retention over 4000 cycles.

Typical commercial Li-ion batteries contain graphitic anodes; however, these are not suitable for high-powered applications due to poor performance at high currents. As such, new anode materials must be explored. Iron oxide materials are attractive anode candidates due to their high theoretical capacity, good reduction potential, and easy synthesis, as well as their low cost, abundance, and eco-friendliness. Unfortunately, such anodes tend to suffer from a high irreversible capacity loss after the first few cycles, when used with conventional cathodes.

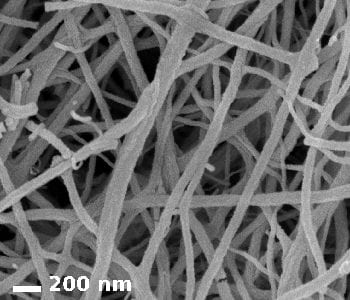

The high-performance battery demonstrated here is constructed of a hierarchical hematite nanofiber anode, with a typical spinel LiNO4 cathode and LiPF6 electrolyte. Performance of the anode is greatly enhanced after a prelithitation treatment. The nanofiber anode is prepared by an electrospinning technique, which is scalable to large scale production. The resulting fibers are of single phase α-Fe2O3, with crystallites of approximately 46 nm. The fibers themselves have a nanoporous structure, such that the anode is formed of a mat of interwoven, nanoporous fibers, allowing for excellent penetration of the electrolyte and more efficient electrochemical reaction. On testing the untreated nanofiber anode against a Li cathode, it is found that several reactions take place in the first cycle, leading to irreversible capacity loss due to the decomposition of electrolyte and formation of a resistive solid–electrolyte interface layer on the anode.

However, prelithiation treatment of the anode greatly improves the initial irreversible capacity loss. When the prelithiated anode is used in a full-cell Li-ion battery, the battery displays excellent performance in long term cyclability at high currents, with 70% of initial capacity retained over 4000 cycles; to date, the best reported cyclability for a conversion-type anode in a practical configuration. Both the prelithiation and the electrospinning techniques applied to fabricate this high-performance battery are fully scalable, and such an anode is therefore suitable for large scale industrial production. This study paves the way for further improvements of the anode and the cell as a whole—such as fine tuning of the electrode through the use of carbon additives or coatings, and optimization of the cathode— to provide further advancements in the quest for high-powered Li-ion batteries for electric vehicles.

Advanced Science is a new journal from the team behind Advanced Materials, Advanced Functional Materials, and Small. The journal is fully Open Access and is free to read now at www.advancedscience.com.