Advanced Engineering Materials has been bringing you the latest breakthroughs in engineering materials that are making those important first steps towards commercialization since 1999, covering key topics such as intermetallics, ceramics and coatings, but also high-temperature, cellular and biomedical materials, with a strong focus on new manufacturing techniques.

No access to our published content? Make sure to recommend Advanced Engineering Materials to your librarian. More information can be found here.

In this monthly feature, we highlight the research behind the artwork on the cover of the most recent issue of Advanced Engineering Materials, as well some of the most read Advanced Engineering Materials publications over the last month. The cover contribution and these top-downloaded articles are therefore currently freely accessible! Click on the titles below to get to the corresponding papers. You can find this month’s issue here.

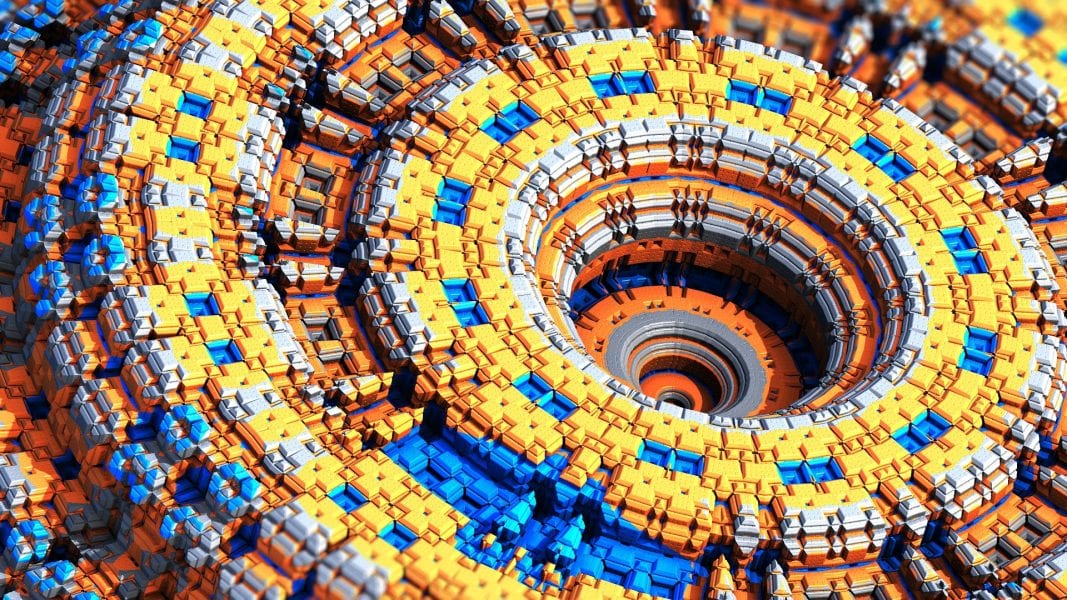

by Li Hong Xia, Bo Yun Huang, Fu Qin Zhang, Lei Jin, Da Chen, and Qian Tang

The background of this month’s cover image illustrates a novel chemical vapor infiltration process to deposit pyrocarbon on the surface of carbon fibers. The images in the foreground show the microstructure of the carbon fiber/pyrocarbon composites at different infiltration temperatures as observed under a polarized microscope. It can be seen that the texture of pyrocarbon deposited by pressure-gradient chemical vapor infiltration is homogenous and can be controlled, as reported here by Fu Qin Zhang and colleagues from the Central South University in Changsha, China.

Tough Nano‐Architectured Conductive Textile Made by Capillary Splicing of Carbon Nanotubes

by Yue Liang, David Sias, Ping Ju Chen, and Sameh Tawfick

Thin metal films are of great importance for flexible electronics. However, their low fracture energy largely limits the performance of such devices. Aligned carbon nanotubes with ideal electrical conductivity and mechanical properties are therefore promising alternatives for flexible devices, but such materials are hard to be constructed. Sameh Tawfick and his collaborators from the University of Illinois at Urbana-Champaign now applied the principles of fracture mechanics to design and synthesize thin carbon nanotube-based textiles, which exhibit both high electrical conductivity and unusually high toughness, and therefore are suitable for applications ranging from smart skins to flexible sensors.

Three Decades of Auxetics Research − Materials with Negative Poisson’s Ratio: A Review

by Krishna Kumar Saxena, Raj Das, and Emilio P. Calius

Auxetic structures are a new class of metamaterials that have a negative Poisson’s ratio, meaning that when compressed in longitudinal direction they shorten instead of widen in transverse direction, and vice versa. This interesting behavior allows for significant enhancement of various mechanical properties, potentially leading to novel applications in areas such as medicine, military, sports, and the automotive industry. Krishna Kumar Saxena and co-workers at the University of Auckland, New Zealand present a comprehensive review of these metamaterials, focusing on their properties and applications, and also discussing the state of the art in the design, modeling and fabrication of auxetic structures.

A more extensive news article about this study can be found here.

by Lai-Chang Zhang and Hooyar Attar

Titanium materials are of particular interest for biomedical applications due to their outstanding biocompatibility, excellent corrosion resistance and appropriate mechanical properties. However, difficulties with the required machinery and the high costs of material removal, which arise from the conventional multi-step manufacturing processes, usually make titanium components expensive. Emerging advanced manufacturing technologies such as selective laser melting (SLM) are providing the ideal platform for the creation of customized titanium-based devices. This article by Lai-Chang Zhang and Hooyar Attar from the Edith Cowan University in Perth, Australia reviews the recent progresses in SLM of titanium alloys and titanium matrix composites.

A more extensive news article about this study can be found here.

Densification of Carbon/Carbon Composites Plate by Pressure-Gradient Chemical Vapor Infiltration

Densification of Carbon/Carbon Composites Plate by Pressure-Gradient Chemical Vapor Infiltration