Dielectric elastomers were previously synonymous with artificial muscles due to their close resemblance to human skeletal muscles with respect to mechanical and physical properties. As for human muscles, it is desired to have as low as possible thickness and thereby weight, while maintaining the performance. Furthermore, defects in muscles cause failure. For dielectric elastomers defects usually cause irreversible breakdown of the given dielectric elastomer product, whereas human muscles are capable of self-repair. No versatile self-healing material fulfilling all the required specifications for dielectric elastomers has been developed up to now, and thus in order to be commercially attractive, the dielectric elastomer film needs to contain as little defects as possible from the beginning, i.e., the elastomer must be as homogeneous as possible. This puts demands to the production of these micrometer thin films, which furthermore are highly elastic to complicate the processing even further. Therefore new characterization techniques for detection of film quality are required since the most commonly utilized techniques for online thin film characterization fail.

Silicone elastomers, which are the most commonly utilized elastomers for dielectric elastomer products, consist of – in principle – very long silicone polymer chains with end-group functionality, which are then crosslinked by means of a relatively small but highly functional crosslinker. The concentration of the reacting moieties is very low in order to give the elastic, soft nature of the elastomer. The crosslinker and polymer also have almost identical refractive indices. Therefore, traditional spectroscopic methods cannot be used for neither qualitative nor quantitative interpretation of the local homogeneity since the signals will be below the detection limit.

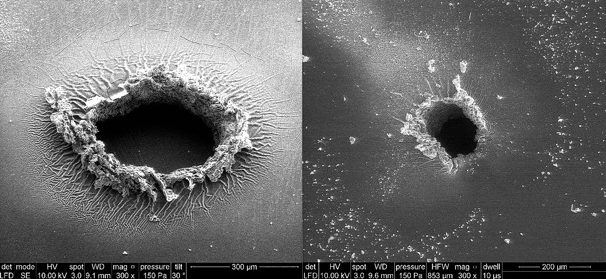

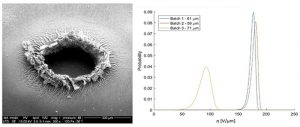

Within this work published recently in Advanced Engineering Materials, A.L. Skov et al. from Technical University of Denmark deal with mechanical and electrical characterization of silicone-based dielectric elastomer films as a means to evaluate the homogeneity of the films. The ultimate mechanical properties are shown not being able to distinguish clearly between homogeneous and inhomogeneous films since inhomogeneity to some extent improves mechanical properties of elastomers. However, when the electrical breakdown strength is used as a measure of the homogeneity an unambiguous interpretation of the data results upon Weibull analysis of the resulting electrical breakdown strengths. The proposed method can clearly identify improper mixing as well as inhibition of the crosslinking reaction and therefore paves the way towards versatile, online detection of film quality.