Titanium is widely used in biomedical fields due to its good biological performance and good mechanical properties. To avoid problems such as infection after insertion of implants a combination of drug and device is a promising approach. The convergence of technologies in which biology is combined with drug-release systems and medical devices is the main trend in the near future.

Titanium is widely used in biomedical fields due to its good biological performance and good mechanical properties. To avoid problems such as infection after insertion of implants a combination of drug and device is a promising approach. The convergence of technologies in which biology is combined with drug-release systems and medical devices is the main trend in the near future.

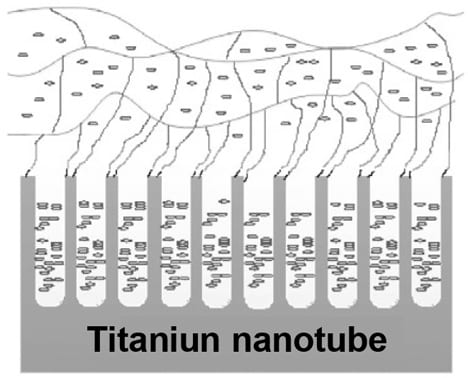

The fabrication of titanium nanotubes as drug delivery carriers is state of the art, but the release of drugs is still uncontrolled. Therefore, Kaiyong Cai, Feng Jiang, Zhong Luo and Xiuyong Chen explored the feasibility of controlled drug release from titanium nanotubes at the Chongqing University in China. They intended to develop a temperature-responsive controlled drug release by introducing a covering layer of hydrogel onto the titanium nanotubes.

They fabricated the titanium nanotubes via anodic oxidation using mixture electrolyte containing ammonium fluoride, water, and glycerol. The titanium nanotubes were in situ formed onto the surface of titanium foils. As model drug Vitamin B2 was employed in this study.

To prepare a temperature responsive hydrogel the scientists used the polymer PNIPAAm. Its lower critical solution temperature (LCST) is around 32–34°C. Since the LCST of PNIPAAm is lower than physiological temperature of 37°C, the researches increased the LCST by copolymerization with other monomers.

Around the LCST, hydrogel undergoes a reversible volume phase transition: When the temperature is lower than the LCST, the composite hydrogel is in a highly water swollen state. Whereas the hydrogel is in a collapsing state to allow drug releasing from underlying titanium nanotube once the temperature increases above the LCST of composite hydrogel.

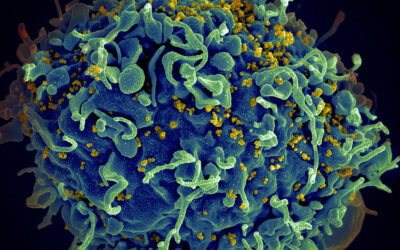

An inflammatory reaction will lead to a local temperature increasing to more than 38°C. This temperature change is the direct stimulus to trigger temperature-responsive drug delivery system to release drug for local drug therapy.

Scanning electron microscopy (SEM) and Fourier transform infrared spectroscopy (FTIR) verified that this system was successfully constructed. The drug release profiles demonstrated the temperature responsive drug release performance. The controlled drug release from titanium nanotubes as presented in this work has potential application in future titanium-based implants.