Do you remember the time when you were playing with magnets? Some of us still do!

Do you remember the time when you were playing with magnets? Some of us still do!

Recently, Sanjay Mathur and coworkers from the Institute of Inorganic Chemistry at the University of Cologne developed a new method for the fabrication of anisotropic iron oxide nanostructures through the application of magnetic field in plasma enhanced chemical vapor deposition (PECVD) using Fe(CO)5 as a molecular precursor.

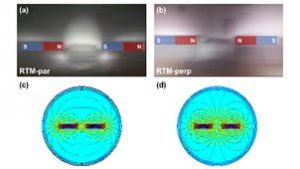

The authors report on the influence of external magnetic fields, applied parallel or perpendicular to the substrate, during PECVD of hematite (α‐Fe2O3) nanostructures.

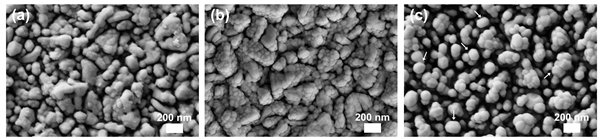

Hematite films grown from iron precursors show pronounced changes in phase composition (pure hematite vs. coexistence of hematite and magnetite) and crystallographic textures depending upon whether PECVD is performed with or without the influence of an external magnetic field.

Static magnetic fields created by rod‐type (RTMs) or disk‐type magnets (DTMs) results in hematite films with anisotropic or equiaxed grains, respectively. Using RTMs, a superior photoelectrochemical (PEC) performance is obtained for hematite photoanodes synthesized under a perpendicularly-applied magnetic field (with respect to substrate), whereas a parallel magnetic field results in the most efficient hematite photoanode in the case of DTM.

The experimental data on microstructure and functional properties of hematite films show that the application of magnetic fields has a significant effect on the crystallite size and texture with preferred growth and/or suppression of grains with specific texture in Fe2O3 films.

Investigations on the water splitting properties of the hematite films in a PEC reactor reveal that photocurrent values of hematite photoanodes are remarkably different for films deposited with (0.659 mA cm-2) or without (0.484 mA cm-2) an external magnetic field.

“Within our priority program funded by the DFG [Deutsche Forschungsgemeinschaft] we investigate new strategies to synthesize and process inorganic materials with better properties and by consuming less resources and energy.” said Prof. Dr. Olivier Guillon, coordinator of the Priority Programme SPP1959 funded by the German Research Foundation (DFG).

“Within our priority program funded by the DFG [Deutsche Forschungsgemeinschaft] we investigate new strategies to synthesize and process inorganic materials with better properties and by consuming less resources and energy.” said Prof. Dr. Olivier Guillon, coordinator of the Priority Programme SPP1959 funded by the German Research Foundation (DFG).

“The use of external electric and magnetic [fields] is particularly effective for achieving tailored microstructures, which are not possible otherwise.”