Combustible insulation materials are responsible for most fatal fires. The massive use of these kinds of commercial insulation materials, such as expanded polystyrene (EPS) and polyurethane foam (PU), are a great hazard in high-rise buildings.

Indeed, recent accidents have highlighted the importance of s tructural integrity and thermal shielding of insulating materials at high temperature to prevent or minimize the risk of thermally induced collapse of buildings.

tructural integrity and thermal shielding of insulating materials at high temperature to prevent or minimize the risk of thermally induced collapse of buildings.

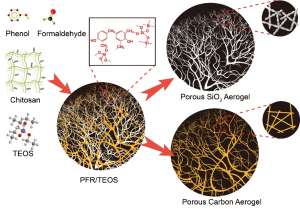

In their Communication in Angewandte Chemie International Edition, Prof. Shu-Hong Yu and co-workers at the University of Science and Technology of China report a novel binary network phenolic–silica aerogel with a nanoscale homogeneity prepared via co-polymerization and nanoscale phase separation strategy.

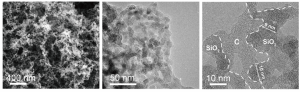

During the co-polymerization, phase separation occurs at the nanoscale, forming homogeneous binary network microstructures with a typical domain size around ≈20 nm. The low density and high porosity ensure a low thermal conductivity of 24 mW m−1 K−1, which is significantly lower than that of commercial insulation materials like EPS. The unique binary network microstructure endows the aerogel excellent fire resistance. While the organic phase would be burned off over time in a fire, the exposed inorganic network would take on the responsibility of further fire-resistance.

The microstructure of the binary network aerogel.

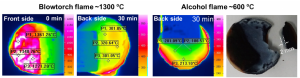

A high-temperature flame of ≈1300ºC and ≈600ºC was used to evaluate the time-dependent fire-resistance of the aerogel for 30 mins. The front side temperature increases up to a maximum temperature of ≈300 ºC. Under an alcohol lamp flame, the temperature at the rear was still below 200ºC. The silica shell at the front side was firmly integrated and structural integrity well reserved. The binary network aerogel could provide extended protection against fire-induced collapse of reinforced concrete structures.