The development of conductive nanomaterials for lightweight, flexible bio-electronics in various biomedical applications, such as blood glucose sensors, tissue monitors, neuron-to-machine interfaces, and artificial electronic muscles and skins, has attracted tremendous attention over the last decade.

These flexible bio-electronics that can be fabricated from conductive nanostructures on flexible substrates, demonstrate functions that highly rely on the intrinsic properties of the individual components. To simplify the fabrication process and to extend their functionalities, researchers have been studying new types of conductive materials that are both inexpensive to synthesize and widely adaptable to current manufacturing processes.

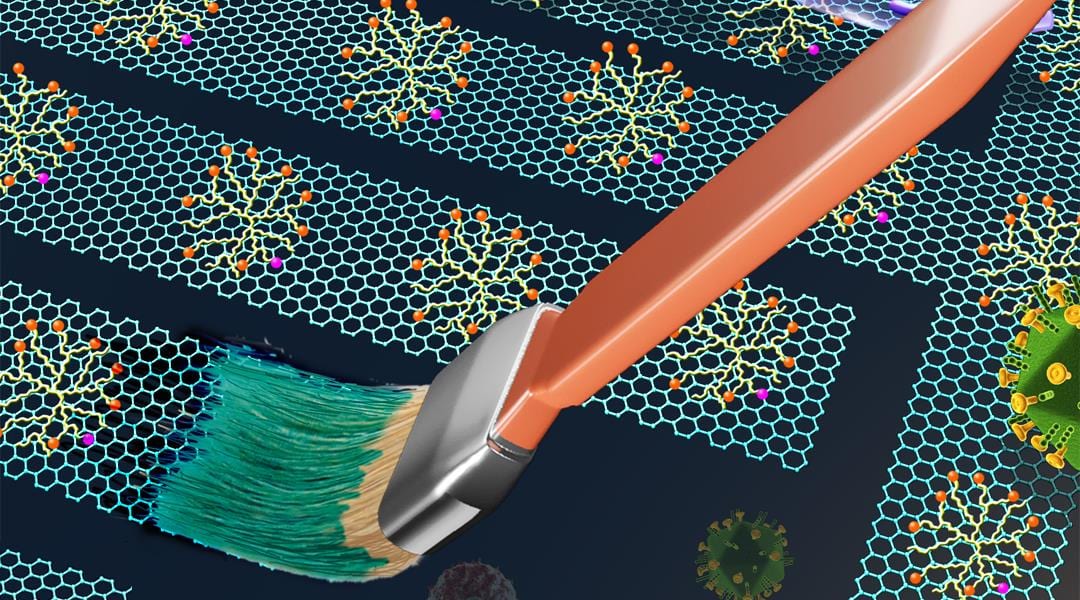

Among these, liquid nano-inks, rank particularly high, with graphene nano (GN) inks being a top choice for bio-electronic applications. The main reasons for that are, on one hand the combination of unique properties exhibited by graphene, such as high conductivity, flexibility, chemical and biological stability, and on the other, the fact that grpahene can be easily manipulated to produce 2D conductive nano-inks in liquid phase.

Although the concept is simple, the fabrication of bioactive, highly conductive and colloidal stable GN inks still remains a great challenge within the research community predominantly due to easily-scalable macromoleules being unavailable to be dispersed on graphene as a first step toward the synthesis of GN inks.

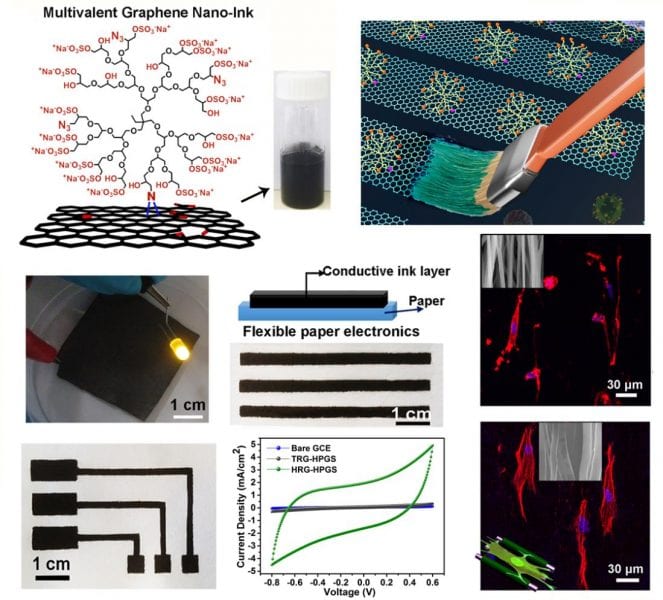

In their work published in Advanced Materials, Prof. Rainer Haag and his co-workers at Freie Universität in Berlin, describe how they obtained state of the art GN inks based on a facile and scalable strategy that allowed them to synthesize conductive, water-processable, bioactive GN-inks. By attaching biocompatible and multivalent electrolytes to the graphene surface, they enhanced the stability of graphene in water and biological fluids.

The obtained ink exhibited a well-defined and flat 2D morphology, good electronic-cellular activity and good adaptability to conventional coating/printing processes. Notably, this is the first study to report a highly facile strategy for fabricating conductive bioelectronics nanofibers that are flexible, while retaining a uniform 3D morphology.

“We have designed an inexpensive and scalable pathway to develop a water-processable and bioactive graphene nano-ink for exploiting its potential application in biomedicine”, said the researchers. Before going on to add, “We hope this protocol becomes a novel and powerful tool for many future studies, such as cell morphology guidance, stem cell differentiation controlling, artificial muscle, spinal nerve repair, and electronic implants”.