A new silk ink formulation provides a "bottom-up" approach to customized multifunction biomaterials.

The design of biomaterials has always been function-oriented, which leads to a highly divergent variety of fabrication strategies targeting very specific applications. While such a trend in the development of biomaterials is likely to provide well-tailored end products with precisely defined functions, it falls short of the ability to integrate multifunctional features that are often required to address complex needs at biological interfaces.

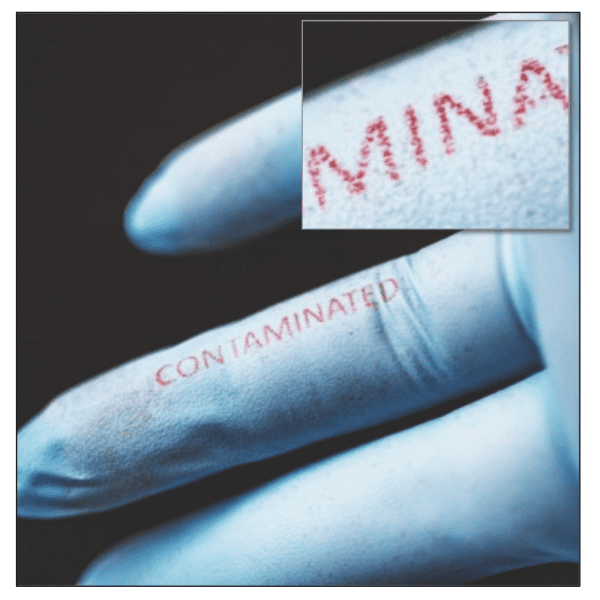

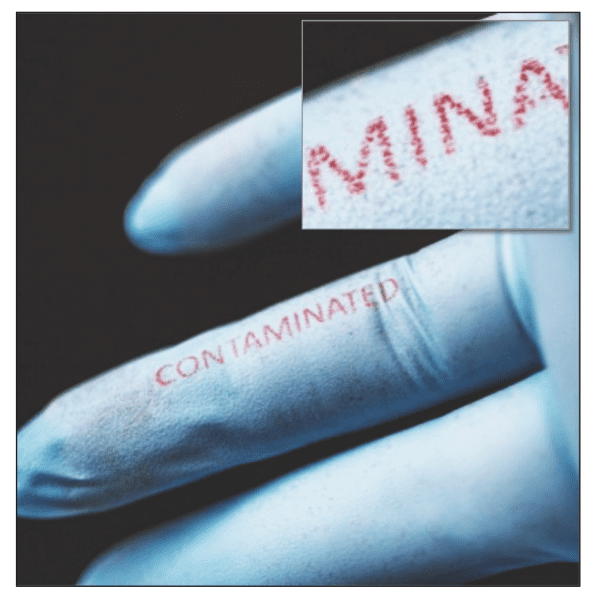

While being mechanically robust, silk, a common and inexpensive material, can also help preserve the bio-functionality of small molecules, extending the shelf life of printed products. Starting from cocoons produced by silkworms (Bombyx mori), the silk ink can be prepared as a fibroin aqueous solution after degumming, extraction, and purification, and its rheological properties are tunable by changing processing conditions, as well as silk concentrations. Then the researchers have prepared a library of functional silk inks by adding nanoparticles, enzymes, antibiotics, growth factors, and antibodies to the stock ink solutions. Using a commercial inkjet printer, they are able to designed patterns with high precision on various substrates. In particular, the horseradish peroxidase in silk ink is stabilized over an extended period of time, whereas polydiacetylenes/goat IgG antibody-containing ink can be printed for on demand colorimetric bacterial sensing.

As a versatile inkjet printing platform, the scope of dopants for making new inks is not limited to just biomolecules, and can be readily extended to include quantum dots and fluorescent dyes, among other materials and material combinations. In this case, Omenetto points out that “multi-cartridge printing can bring together multiple inks to easily obtain complex combination of functional inks or multi-functional interfaces where organic and inorganic inks are printed together”, which is certainly a direction of future exploration.

The authors expect to achieve new modalities of sensing by printing multiple chemistries, which will add more sophistication to various surfaces – “we plan on extending the work on sensing gloves to obtain more specificity and selectivity”, Omenetto says. Taking advantage of the inkjet print technique, he also sees the possibility of defining topographically complex patterns, concentrations, and chemical gradients, enabling “in-vitro screens and models that can assist in tissue engineering studies”, as well as “appropriate bio-printouts that are matched and adapt to certain topographies”, where he uses “printing a smart band aid with a distribution of therapeutics matched to a complex wound” as an example.