One of the most promising next-generation photovoltaic technologies is the Organo–lead halide perovskite solar cells. These solar cells have reached very high power conversion efficiencies (PCE) of more than 22% and in addition, their semiconducting perovskite layer can be fabricated by solution processing, which virtually ensures their low cost.

However, for most of the high performance perovskite solar cells, the metal top electrode is typically prepared by vacuum based thermal evaporation, which is not compatible with roll-to-roll printing process and is therefore considered a bottleneck for the realization of low-cost perovskite solar cells.

The preparation of metal top electrode by solution processing is challenging, due to, on one hand, to the high sensitivity  of the perovskite thin films to the solvent, and on the other hand due to the poor interfacial connection between the functional layer and the printed top electrode.

of the perovskite thin films to the solvent, and on the other hand due to the poor interfacial connection between the functional layer and the printed top electrode.

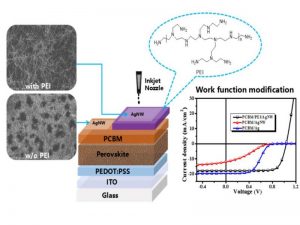

In a paper in Solar-RRL, scientists from China demonstrate the performance of solar cells with printed AgNW top electrode directly on the PC61BM layer. By carefully comparing the performance of devices with different metal electrodes, they show that the mismatched work functions of AgNW electrode and PC61BM layer, and in addition, the solvent assisted chemical corrosion of the AgNW electrode by halogen anions, are the main reasons for the low device performance.

Based on this understanding, they introduce a thin layer of polyethylenimine (PEI) between PC61BM and AgNW electrode. This interfacial layer improves the charge injection efficiency at the PC61BM and AgNW interface and the chemical corrosion of AgNW electrode is suppressed, improving both device performance and its stability. Therefore, this work provides a feasible method for the full solution-processed perovskite solar cells.

The text was provided by the authors and edited by Ekaterina Perets.