Robots let scientists explore places humans can’t go, like distant planets, tiny crevices within archaeological sites, and the ocean floor. But traditional robots can be destructive, especially in environments that contain sensitive organisms, with marine habitats being one such example.

Researchers at Carnegie Mellon University are tackling this problem with robotic actuators made from biodegradable calcium-alginate. The team says these “soft” actuators — the parts of the robot that produce motion — are a step towards building a gentler, more environmentally friendly marine robot.

Victoria Webster-Wood is one of the researchers who worked on the study. “The early manufacturing robots […] they were these huge metal arms, and they essentially had cages around them because they were so dangerous that you didn’t want human operators getting anywhere close,” she said. “But if you can add ‘squish,’ if you can add — we call it ‘compliance’ — to the robot, then it’s a lot safer.”

Soft robots to explore fragile environments

This idea is especially important for the marine environment, where researchers often work with and around organisms that can be easily injured. Webster-Wood uses jellyfish as an example. “That’s a very small, fragile critter,” she explained, “and if we [grab] it with a rigid robot, you could damage it. But the soft robot is kind of cushioned.” The cushion, Webster-Wood says, helps limit or eliminate damage.

The Carnegie Mellon team built three different actuator structures, including a two-fingered soft gripper, the part of the robot that is used to grasp and pick up things in its environment. “Each finger is designed so that it has an internal cavity,” said Webster-Wood. “We just use a syringe pump to change the pressure inside the fingers. When you pressurize them, they bend towards each other. That’s what causes that gripping motion.”

Similar grippers already exist in soft robotics, but most are made from synthetic materials like polystyrene and silver epoxy, which don’t biodegrade and can be toxic to marine life. This is a significant problem in hard-to-reach marine habitats, especially if robots become disabled or lost, they will pollute or become a danger to animals that try to eat them.

The material developed by the Carnegie Mellon team is a 3D-printed “hydrogel” derived from brown seaweed. The soft robots made from the material would be deployed in areas where brown seaweed is native, so they would have a limited environmental impact even if they could not be retrieved from the marine environment after use.

The slug test

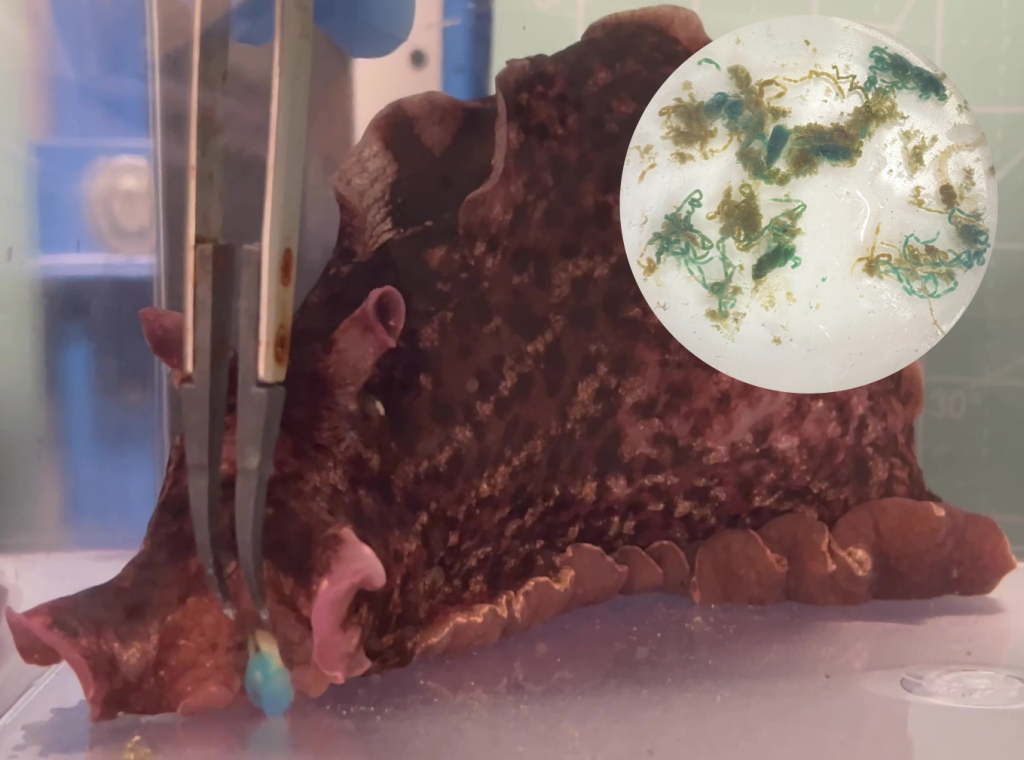

The actuators are biodegradable and also non-toxic. “One of the important things to us was that they were safely edible,” said Webster-Wood, who also works with sea slugs in her laboratory. “[Sea slugs] naturally eat seaweed, so we just offered actuators to the sea slugs.”

The slugs were fed a combined diet of actuators and seaweed for a total of 29 days. “This is probably getting a little weird,” Webster-Wood laughed. “We monitored their detritus. The slug poop. [The actuators] were being safely digested.”

Soft marine robots have great potential for helping scientists explore marine environments in the least impactful way possible, but actuators are only part of a working robot. More research needs to be done before it will be possible to build a completely biodegradable robot.

Other recent papers have noted that there are still many challenges to overcome before soft marine robots will be practical for all applications. For example, they may not be tough enough to explore remote areas in the deepest parts of the ocean. Most are “tethered”, which means they can only be deployed short distances. An untethered robot would also need its own power supply, adding to the challenges of building a completely biodegradable and edible unit.

“The electronics are where things start to get a little more challenging,” said Webster-Wood. Still, she envisions a future with “fully biodegradable robots made out of materials that we can farm, that are sustainable, that are environmentally friendly”, and is optimistic that the challenges can be overcome.

“I’ve seen some really cool papers about biodegradable electronics,” she said, “which is why I don’t think it’s impossible.”

Reference: Victoria A. Webster-Wood, et al., Biodegradable, Sustainable Hydrogel Actuators with Shape and Stiffness Morphing Capabilities via Embedded 3D Printing, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202303659

Images provided by Victoria Webster-Wood