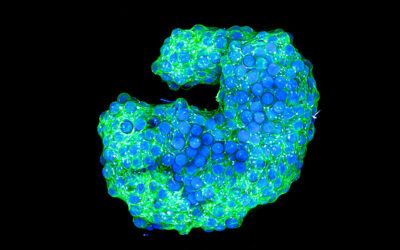

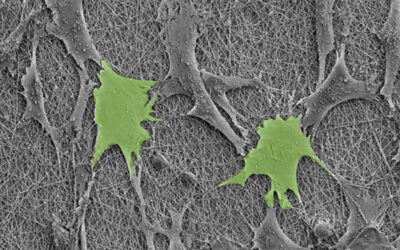

Biomedical engineering is a fast-growing field that has experienced numerous advances over the past few decades. Additive manufacturing technologies (AMTs) are used in biomedical engineering to improve the qualities of materials that are used in medical devices, surgical guides, and implants for regenerative therapy. Implants in particular rely on lithography-based AMTs (L-AMTs), in which photosensitive resins are used to produce scaffolds for tissue engineering to replace a structure in a biological system.

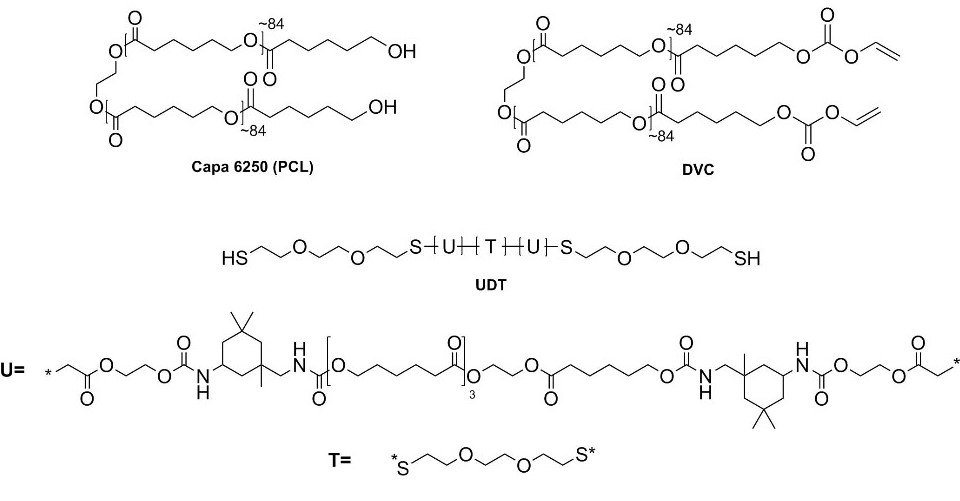

Structures of the additives: Capa6250 (PCL), divinyl carbonate modified PCL (DVC), and urethane dithiol (UDT).

In their study published in the Journal of Polymer Science, Part A: Polymer Chemistry, Sandra Orman and team sought to improve upon an existing tissue engineering scaffold that has lingering shortcomings.

Tissue engineering faces the obstacle of having scaffolds that have appropriate mechanical properties for multiple different applications. The photosensitive resins that are often used to produce these scaffolds generally lack sufficient toughness.

Vinyl esters, which have recently been established as apt replacements for (meth)acrylates as precursors for photopolymers, suffer from brittleness. While the vinyl esters have low cytotoxicity, high biocompatibility, and favorable degradation behavior, their structural shortcomings have been a topic of research.

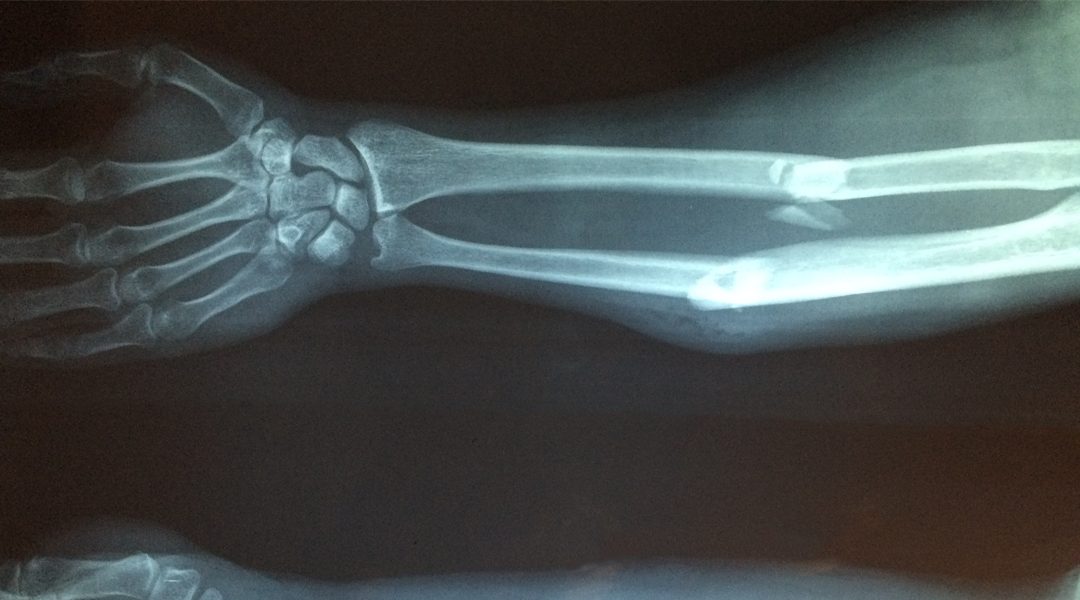

Existing research has used chain-transfer agents, or CTAs, like thiols in an attempt to overcome the structural problems facing the vinyl ester-based photopolymers. These studies successfully fabricated scaffolding from this method, however these scaffolds still lacked the toughness required for bone graft substitutes and screwed implants.

The study completed by Orman and colleagues sought to overcome this remaining structural shortcoming of the existing photopolymerizable vinyl ester-based thiol-ene scaffolding by designing and preparing molecules and oligomers using three additives: Capa6250 (PCL), divinyl carbonate modified PCL (DVC), and urethane dithiol (UDT).

Orman and team tested all the resulting molecules for reactivity, toughness, and other mechanical properties. They found that the molecules with the additives ultimately doubled the impact resistance of the existing scaffolding networks. This was the primary intention of their experiment.

The team reports that future research will need to study the fabrication of these new scaffolds using digital light processing-based stereolithography (DLP-SLA) to confirm that the scaffolds are applicable in bone tissue engineering. The degradation characteristics of the photopolymer networks containing the three tested additives from this experiment will also need to be investigated.