CSIRO scientists have developed new nanosensors capable of detecting very low concentrations of toxic gases such as ammonia and nitrogen dioxide, and which can be reset using water molecules or ethanol.

CSIRO scientists have developed new nanosensors capable of detecting very low concentrations of toxic gases such as ammonia and nitrogen dioxide, and which can be reset using water molecules or ethanol.

The breakthrough could lead to the creation of a new generation of medical and industrial devices which can hone in on molecules important in environment and in medical diagnosis. The sensor is made from the nanometer-sized flakes of a material called graphene. CSIRO’s Dr. Lakshman Randeniya and colleagues have developed the sensor in a simple configuration to detect ammonia and nitrogen dioxide, but they believe that it could be modified to detect many other types of molecules. The new approach also avoids expensive device fabrication.

In lab tests, the team detected ammonia molecules down to one part per million (lower detection limit of 200 parts per billion) and nitrogen dioxide down to 500 parts per billion (lower detection limit of 100 parts per billion), bettering previously recorded results for graphene-based sensors with a simple device configuration.

Dr Randeniya believes the sensor could be used to determine a number of environmental pollutants causing respiratory diseases. Further, measuring breath ammonia levels can be a fast diagnostic method for patients with a disturbed urea balance, e.g., due to a kidney disorder or ulcers caused by Helicobacter pylori bacteria stomach infections. For such applications, often only small samples of exhaled air are available and, at present, no suitable ammonia breath analyser exists. Suitable ammonia analysers should be able to measure down to 50 parts per billion of ammonia in exhaled air, containing CO2 concentrations up to 3%.

Graphene has been hailed as a super material for its unique properties, which include very high electrical conductivity and very low electronic noise. One of the major advantages of the new nanosensor is that it can be used at room temperature and can be regenerated for making repeated measurements.

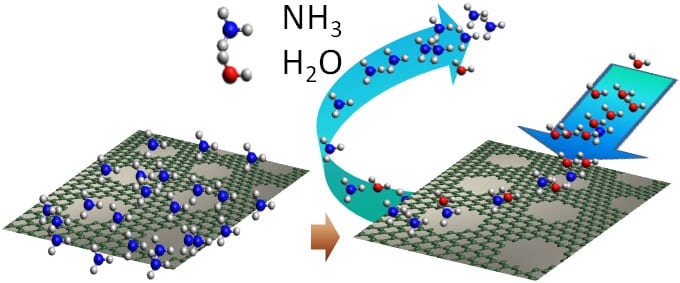

In traditional room-temperature nano-structured sensors, gases tend to adsorb strongly onto the material and hamper recovery and repeatability. This is typically overcome by heating the material or exposing it to UV light, but this in turn degrades the performance of the sensor.

The sensors were created by depositing processed nanosized flakes of graphene on to a material called mesoporous alumina membranes. This method exposes a high density of reactive edges, which makes the sensor ultra-sensitive.