Surface tension allows insects to walk on water and gives integrity to soap bubbles. If soap, having a low surface tension, is added to an aqueous dispersion of higher surface tension, the situation becomes more interesting. Even coffee stains demonstrate this so-called “Marangoni effect”, which must be controlled to improve the homogeneity of bar coating—a common solution-based deposition method used in semiconductor manufacturing.

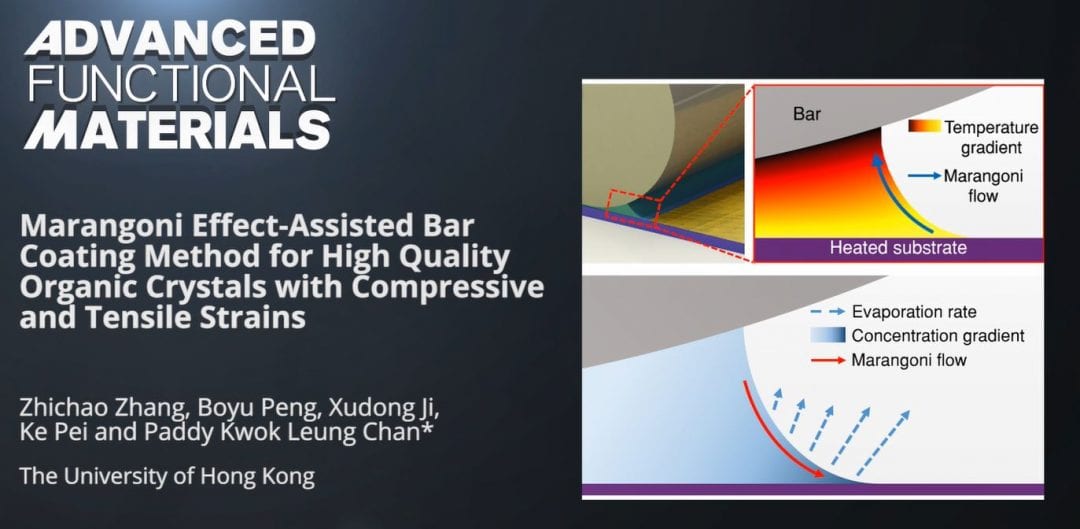

In their recent full paper in Advanced Functional Materials, Paddy Kwok Leung Chan and his co-workers from the University of Hong Kong report how solution shearing of organic semiconductor crystals is influenced by a surface tension gradient. Using a Marangoni-effect-assisted bar coating method, ultrathin, uniform layers of crystals with large domain sizes are obtained that show excellent performance in organic field-effect transistors.

The researchers use a heated bar coating setup and apply a meta-xylene solution of C8-BTBT (a benzothiophene derivative) into the gap between bar and substrate. When the substrate is moved at moderate constant speeds, high-quality crystal deposition is achieved. However, larger shearing speed produces a thinner coating with more defects—an increase from 100 µm/s to 400 µm/s reduces coverage from 100% to 73%. Bottom-gate, top-contact organic-field-effect transistors assembled from these films deteriorate in performance for coating speeds higher than 200 µm/s.

The heated substrate induces a Marangoni flow away from the low surface tension region at the surface, causing coating defects by decreasing the semiconductor molecule concentration at the contact line. Simulations indicate a Marangoni flow up to 300 mm/s in meta-xylene—several thousand times faster than the coating speed.

The less volatile ortho-dichlorobenzene enriches at the contact line, generating a region of higher surface tension that accumulates the organic molecules.

To find out more about this fast, low-cost, and large-scale deposition method for high-performance organic field-effect transistors, please visit the Advanced Functional Materials homepage.