Photoelectrochemical (PEC) water splitting is a sustainable approach for the chemical storage of solar energy using semiconductor materials to capture sunlight and convert it to hydrogen. In this context, hematite (Fe2O3) turned out as a particularly well-suited photoanode material owing to its availability, stability, and suitable bandgap for visible light absorption. In the fabrication process of hematite nanostructures the activation via high-temperature annealing (HTA) at 800 °C has emerged as a key step for enhancing the PEC performance of the photoanodes. Nevertheless, the fact that efficiencies are still below the expected values stems from morphology evolution upon annealing that impedes charge separation and slows down charge transfer. To this end, further improvements in the fabrication of hematite nanostructures are pursued to better control the morphology.

Photoelectrochemical (PEC) water splitting is a sustainable approach for the chemical storage of solar energy using semiconductor materials to capture sunlight and convert it to hydrogen. In this context, hematite (Fe2O3) turned out as a particularly well-suited photoanode material owing to its availability, stability, and suitable bandgap for visible light absorption. In the fabrication process of hematite nanostructures the activation via high-temperature annealing (HTA) at 800 °C has emerged as a key step for enhancing the PEC performance of the photoanodes. Nevertheless, the fact that efficiencies are still below the expected values stems from morphology evolution upon annealing that impedes charge separation and slows down charge transfer. To this end, further improvements in the fabrication of hematite nanostructures are pursued to better control the morphology.

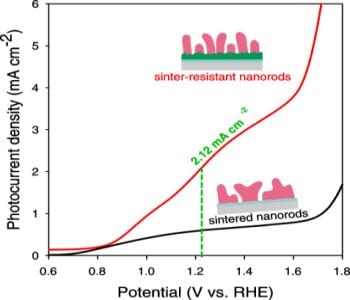

C. Peng, C. Fan, and co-workers present a strategy to retain the morphology of hematite nanostructures under HTA. A closer look on the thermodynamics of hematite activation and sintering reveals that the required temperature for hematite activation is higher than its sintering temperature which provokes the morphology change. As the sintering temperature is directly linked to the hematite crystallinity, improving the latter increases the sintering temperature. C. Peng, C. Fan, and co-workers fine tune the crystallinity be using high-crystalline hematite nanorods grown on fluorine-doped tin oxide (FTO) substrates decorated with antimony-doped tin oxide nanoparticles. With this approach they obtain high photocurrent densities of 2.12 mA cm-2 at 1.23 V (vs reversible hydrogen electrode) which makes this method suitable for use in applications such as dye-sensitized solar cells, water electrolysis and supercapacitors.

Advanced Science is a new journal from the team behind Advanced Materials, Advanced Functional Materials, and Small. The journal is fully Open Access and is free to read now at www.advancedscience.com.