This article was kindly contributed by Prof. Thomas M. Brown at CHOSE (Centre for Hybrid and Organic Solar Energy), Department of Electronic Engineering, University of Rome Tor Vergata.

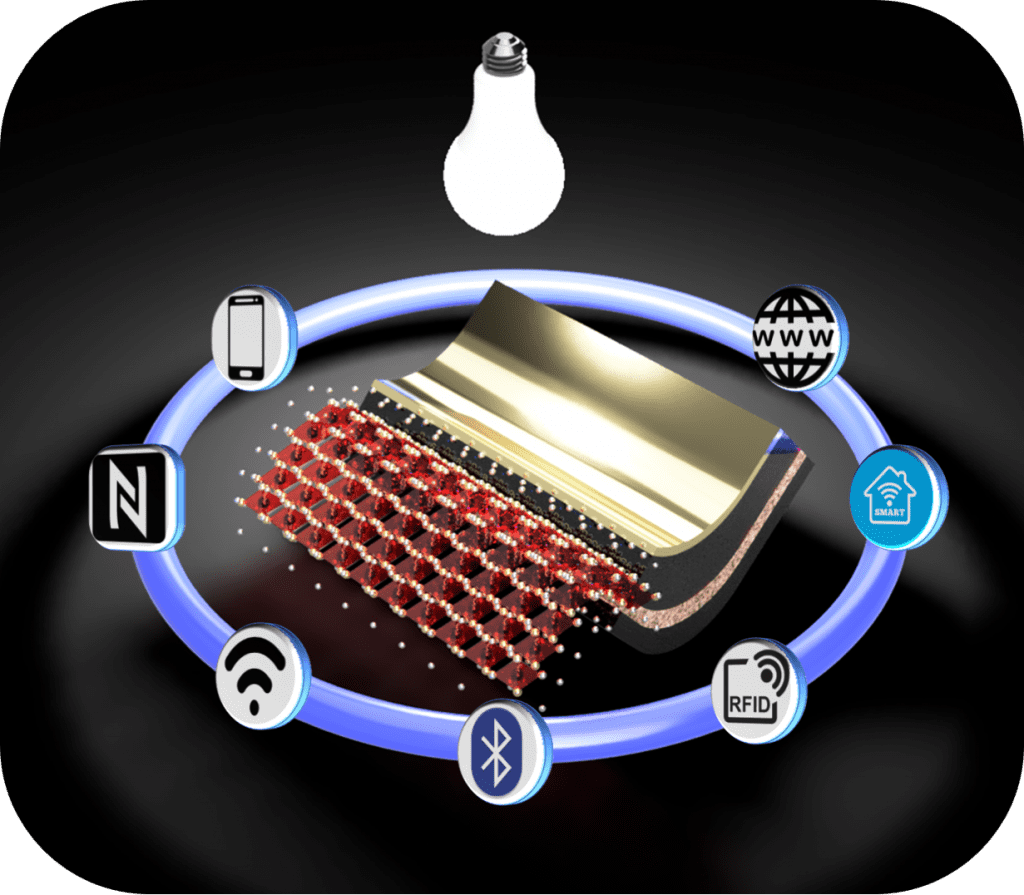

A revolution is already underway in the development of low-power consumer electronics, which includes a huge range of devices such as wireless sensors, computing devices, and controls to be used in smart homes for automation of lighting, entertainment, and appliances, as well as for security through access control and alarms, often referred to as “domotics” or the Internet of Things.

The most convenient way of rendering these elements flexible and easy-to-integrate is to use small and highly efficient devices that harvest energy from interior illumination to provide their electrical power and render them autonomous. Billions of wireless sensors are expected to be installed in indoor environments over the coming decades.

There is obviously a great advantage to using indoor photovoltaic (PV) power sources to provide energy to the electronic components, and as PV cells become even more convenient and economical, their progress will enormously facilitate these other technological innovations. New PV cells can also be small-sized and on ultra-thin curvable substrates, enabling low-cost fabrication, so this type of energy supply will eliminate the need for batteries (whose replacement necessitates cost and work) or complex interconnection networks and provide seamless integration.

An important aim of research is to develop devices that can deliver excellent, cost-effective performance under artificial lighting, which in practice is present almost everywhere indoors. From a technical point of view, the cells must work well under the illumination levels prevalent in homes, shops, and offices (i.e., 100-500 lux). These values are much (between a hundred and a thousand times) lower than those found outdoors under the sun (and which are used as standard test conditions for typical solar cells outdoors). Furthermore, these new PV cells must be fully compatible with the spectra of LEDs or other modern types of lamp.

An international team has published the results of their project that works towards these aims in an article in Cell Reports Physical Science.

The team members are from the Centre for Hybrid and Organic Solar Energy (CHOSE), the Department of Electronic Engineering, University of Rome Tor Vergata; the Hydro Engineering and Agricultural Development Research Group (GHIDA), Faculty of Engineering, Universidad Surcolombiana, Neiva, Colombia; and the Fraunhofer Institute for Organic Electronics, Electron Beam, and Plasma Technology (FEP) in Dresden, Germany.

They report high levels of power generation under indoor lighting conditions using flexible perovskite photovoltaic cells. These were manufactured on roll-to-roll, indium tin oxide (ITO)-coated ultra-thin flexible glass substrates, which not only provided excellent optical and electrical properties (transmittance > 80%, and sheet resistance 13 Ω –2) but were also supple and bendable (surpassing 1600 bending procedures at 20.5mm curvature).

ITO is a transparent conductor that enables flow of current as well as passage of light, which is then absorbed by the perovskite semiconductor film. As well as obtaining these notable physical parameters, they also achieved a large leap forward in electrical conversion efficiency by incorporating a porous scaffold made of titanium dioxide nanoparticles over a compact layer of tin oxide (SnO2), reaching 20.6% and 22.6% efficiency under 200 and 400 lux LED illumination, respectively. The thickness of these solar cells on ultra-thin glass is only 100 micrometers, similar to that of a sheet of standard copy or printing paper or to the diameter of a human hair.

These efficiencies are the highest reported for any type of indoor photovoltaic cell technology that is flexible and bendable. These figures also surpass by over a 60% margin the previous best-performing perovskite PV cells on flexible substrates. Furthermore, specific power (i.e., the power measured in watts delivered per gram of weight of the cell) is 40–55% higher than that provided by their counterparts on plastic PET films, and many times greater (an order of magnitude) than those on rigid glass.

These figures underline the great interest and potential for seamless integration of these ultra-thin and ultra-light energy-harvesting devices in indoor electronic components. It is worth noting that all the active layers of the perovskite photovoltaic cells were deposited at low temperature and using “solution processing” (i.e., the materials are dissolved in inks or pastes). This means that printing techniques will permit low-cost roll-to-roll fabrication of such devices on ultra-thin flexible glass for the whole device, not just the ITO layer. Furthermore, glass creates an exceptionally effective permeation barrier for gasses which are known to degrade perovskite materials, and this positive characteristic remains in its flexible form.

The demonstration of these high conversion efficiencies, as well as their seamless integration as small power sources in a variety of devices and products, can produce perovskite solar cells on ultra-thin glass, a key enabling technology for indoor electronics of the future.