Additive biomanufacturing technologies such as melt electrospinning writing (MEW) are at the forefront of tissue engineering research. MEW is a technology that enables scaffolds to be fabricated that exhibit highly defined, micrometer to sub-micrometer features. However, the fabrication of large-volume MEW scaffolds for soft and hard tissue regeneration remains a challenge.

In their paper in Advanced Materials, Professor Dietmar W. Hutmacher and colleagues from Queensland University of Technology and the University of Würzburg provide an understanding of the electrostatic interactions that currently limit scaffold size in MEW, and overcome these limitations with a mechatronic system.

Computational modelling of the MEW printing environment was undertaken, where voltage was either kept constant or altered to maintain constant electrostatic forces. Moreover, the distance of the spinneret to the top layer of the scaffold was kept constant.

Five different MEW scaffolds were produced to experimentally validate the simulation findings.

Due to electrostatic repulsion/attraction phenomena, distortion events such as random fiber placement, polymer beading, and spontaneous fiber ejection back toward the spinneret were observed.

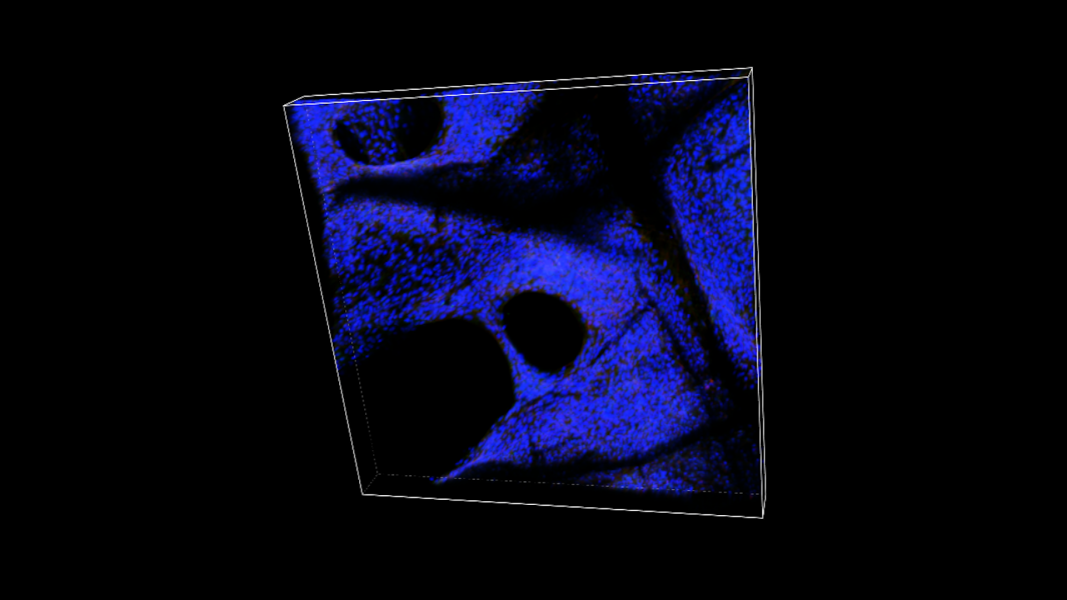

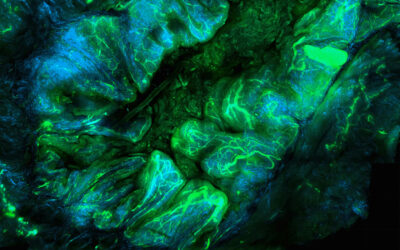

The C1 scaffold was used in cell-seeding experiments to illustrate that these large-volume MEW scaffolds support cell attachment, migration, proliferation, and extracellular matrix formation throughout the scaffold volume.

To find out more about how to construct these highly ordered, large-volume MEW scaffolds, please visit the Advanced Materials homepage.