The fabrication of designed, structurally complex materials occurs effortlessly in nature. The body is made up of many such materials, including ligaments, which possess structural alignment and provide stability for our joints. However, developing synthetic replacements can be quite difficult in the laboratory.

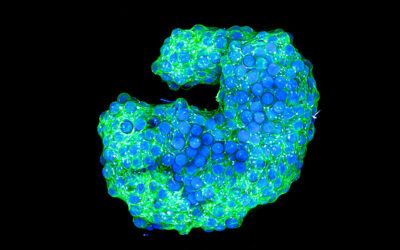

In their communication in Advanced Materials, Professor Jian Ping Gong from the Faculty of Advanced Life Science and the Global Station for Soft Matter at Hokkaido University, Japan, and co-workers present specifically designed structural hydrogels that have applicability in the biomedical field.

Dr. Tariful Islam Mredha states, “In this article, we have provided a general strategy for designing hydrogels with highly-ordered hierarchical structures, which opens routes for the development of many functional biomimetic materials.”

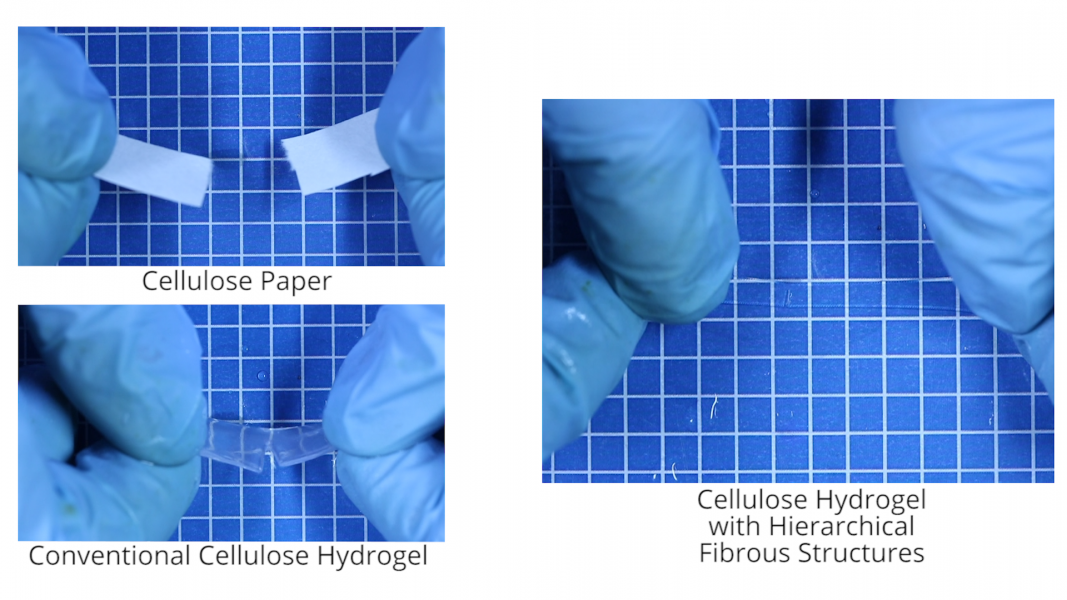

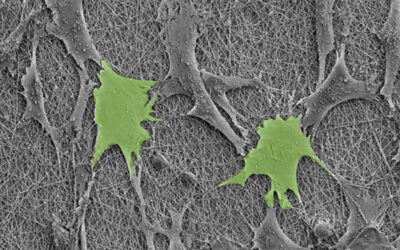

Perfectly aligned, fibrous hydrogels were fabricated using a confinement strategy, where the degree of alignment and superstructure could be controlled by varying the degree of prestretching. Structural analysis of scanning electron microscope images show uniaxially aligned microfibers with distinct sub-micrometer-sized bundles. Each bundle contains nanofibrillar arrays, which are retained in the bulk hydrogel.

The strength of the hierarchically designed hydrogels could be demonstrated in comparison to cellulose paper and to a conventional cellulose hydrogel without the introduction of alignment or superstructure. The cellulose hydrogel containing the hierarchical fibrous structure is markedly stronger, and the mechanical properties are comparable to native ligaments.

To find out more about this method to synthesize hydrogels for biomedical applications, please visit the Advanced Materials homepage.