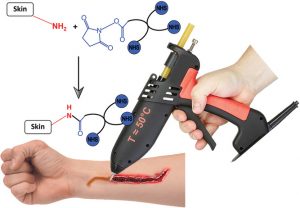

Delivery of glue. Upon application, star‐PCL‐NHS melts and is extruded from the heated nozzle directly and solidifies, closing cuts and wounds.

Most serious injuries are currently treated with pins and stitches, which have many drawbacks. For the patient, they are very painful, leave scars, require high skill from the doctor, and sometimes have to be removed after the tissues heal. Medical glue, on the other hand, can produce improved medical and cosmetic results.

Tissue bioadhesives are widely used in dermatology, surgical theaters, and in the field, but even though they have advantages over sutures and staples, current available tissue glues are limited by their mechanical properties and toxicity. As they are very toxic, they can be utilized only on the surface of the skin. In addition, hardening of the glue may make the organ less flexible or the adhesion may not be sufficiently strong.

With these limitations in mind, researchers have been trying to develop a glue that is suitable for different tissues, non-toxic, and flexible. Such a glue would also need to decompose in the body after the tissue is fused together.

Now, Prof. Boaz Mizrahi and doctoral student, Alona Shagan, from the Technion–Israel Institute of Technology introduce a strong, non-toxic tissue adhesive that remains flexible even after solidification. Melting the glue and smearing it on the damaged tissue is performed with a hot-glue gun. However, unlike the glue guns we are familiar with, this gun warms the glue to a moderate temperature – just above that of the body – so as not to cause a burn. After the glue is applied, it quickly hardens and decomposes within a few weeks. The adhesive is also suitable for the adhesion of tissue inside the body, and it is four times as strong as existing adhesives used for this purpose.

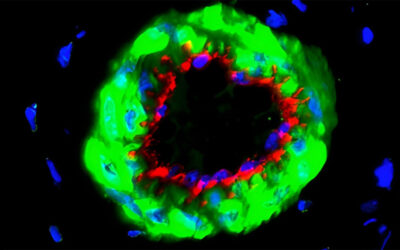

The new approach is based on a biodegradable polyester with a low melting point that is inserted into a hot-melt glue gun and melts upon minimal pressure. It is squeezed directly onto the wound, where it solidifies, bonding with both edges of the wound. Changes in molecular weight allow control of adhesive strength, melting point, and elasticity properties. In vitro and in vivo evaluations confirm the biocompatibility of this system.

The straightforward synthetic scheme and the simple delivery method – combined with the desirable mechanical properties, tenability and tissue compatibility – are desirable traits in wound management.