A growing body of evidence suggests microplastics are harmful to human health — an alarming finding given the presence of microplastics in almost every environment on the planet. The potential health risks and our heavy reliance on plastics drove a sense of responsibility in a group of Australian scientists.

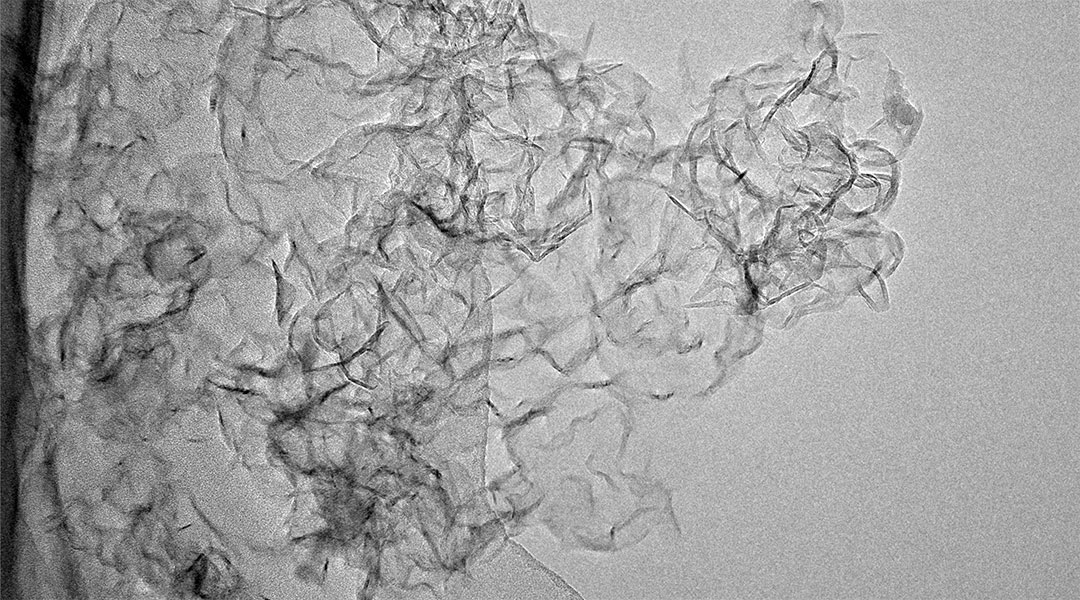

Leveraging their expertise to help solve the problem, they’ve applied an established technology to up-cycle plastic pollution into valuable graphene — a material composed of a single layer of carbon atoms. At this nano-sized scale, it takes on unique properties that make it valuable for electronics, biomedical technology, solar panels, and other hi-tech functions.

Mohan Jacob, a professor of electrical engineering at James Cook University in Australia, has been working for a decade on ways to produce environmentally friendly, sustainable, valued resources, and recently began brainstorming how a technique called atmospheric pressure microwave plasma could be used to transform the carbon in plastic into graphene.

“Atmospheric pressure microwave plasma is an advanced technology that generates plasma at atmospheric pressure using microwave radiation,” Jacob explained.

Plasma is a state of matter consisting of free ions and electrons, which occurs when a gas is subject to high energies. To create atmospheric pressure microwave plasma, microwaves are channeled into a chamber filled with a gas such as argon. This excites the gas and creates the highly reactive plasma.

Using plasma to eliminate microplastics

The technique was previously used to create graphene from methane, ethanol, and oil vapors, but as Jacob explained, using it in combination with microplastics is a breakthrough “because it utilizes solid, environmentally hazardous feedstock, addressing both plastic waste and material synthesis in a novel way.”

When microplastics are put in the chamber with the plasma, they rapidly break down into gases like methane, which is a precursor gas for graphene synthesis. “Methane is significant as it further decomposes in the plasma to release carbon atoms,” explained Jacob. “These carbon atoms then recombine and organize themselves into the hexagonal lattice structure of graphene.”

Compared to other ways of making graphene this method is cleaner, produces little waste and requires minimal pre-processing. “In contrast, traditional methods like Chemical Vapor Deposition (CVD) are more expensive due to high energy and material costs,” said Mohammed Adeel Zafar, co-author of this work and researcher at James Cook University.

He also believes that any cost differences can be offset by the dual benefit of cleaning the environment. “[Atmospheric pressure microwave plasma] not only produces valuable graphene but also removes harmful microplastics from the environment, aligning with sustainability goals and supporting a circular economy,” Zafar said.

Promising first steps, but challenges remain

In experiments published in Small Science, Jacob and his colleagues achieved a six to one conversion ratio. “For example, 30 mg of microplastics yielded 5 mg of graphene,” Jacob said. “Additionally, the quality of the graphene produced was comparable to, and in some cases exceeded, that from conventional sources.” Making it suitable for many commercial uses like electronics, energy storage, composite materials, and environmental technologies.

However, despite these promising results, Jacob does acknowledge challenges with scalability. Currently, the process is not well-suited for plastics with high levels of additives, fillers, or contaminants.

“Additionally, plastics with chlorine, like polyvinyl chloride (PVC), can generate toxic by-products, raising safety and environmental concerns,” he said. “Our team is working on optimizing the process to handle a broader range of microplastics, including those with various additives and contaminants.”

The team is also testing larger reaction chambers with the goal of scaling up the technology and overcoming economic hurdles for large-scale industrial use. “These advancements are essential for making [atmospheric pressure microwave plasma] a viable and widely applicable method for upcycling microplastic waste,” he said.

Reference: Muhammad Adeel Zafar, Mohan V. Jacob, Instant Upcycling of Microplastics into Graphene and Its Environmental Application, Small Science (2024). DOI: 10.1002/smsc.202400176