Imagine a material that conducts electricity like metal but stretches like a rubber band. Now imagine that you can use a ballpoint pen to draw a flexible, wearable circuit with that material. Then, when you’re done, you can easily recycle the conductive material with almost 97% efficiency.

That material is not mythical; it’s called eutectic gallium–indium (EGaIn), a liquid metal at room temperature and highly conductive, it is attracting a lot of attention for its potential applications in flexible electronics.

But EgaIn has one property that makes it tricky to work with: Its very high surface tension means that it tends to ball up into spheres, like water beading on a surface, with individual droplets aggregating to form larger droplets. If you try to spread EgaIn out in a line, it naturally springs back to a sphere.

Researchers hoping to harness EgaIn’s ability to conduct electricity have been searching for ways to overcome this tension so they can freely shape it.

Adding a lignin layer

In a recent study published in Advanced Functional Materials, Lin Dai and Chuanling Si at Tianjin University of Science and Technology in Tianjin, China, and their coworkers have shown that EGaIn can be shaped by encapsulating it in a bio-based material called lignin.

A complex organic polymer, lignin is what gives strength to tree trunks and other plant cells. It is abundant, non-toxic, and best of all, it self-assembles into nano-sized particles. Dai and Si have been working on finding uses for lignin for some time, and its unique aggregation and easy recyclability made them think it would be compatible with liquid metals.

The method Dai and Si used to wrap EgaIn in lignin makes elegant use of both materials’ natural properties and is surprisingly simple: They mixed EgaIn and lignin in solution and sonicated it, which means they vibrated the solution with high-pitched sound waves.

Lignin near the liquid metal naturally adsorbed to its surface then assembled into a shell around the metal droplet. The result was nano-sized EGaIn spheres wrapped in lignin, like infinitesimally small candy-coated chocolates.

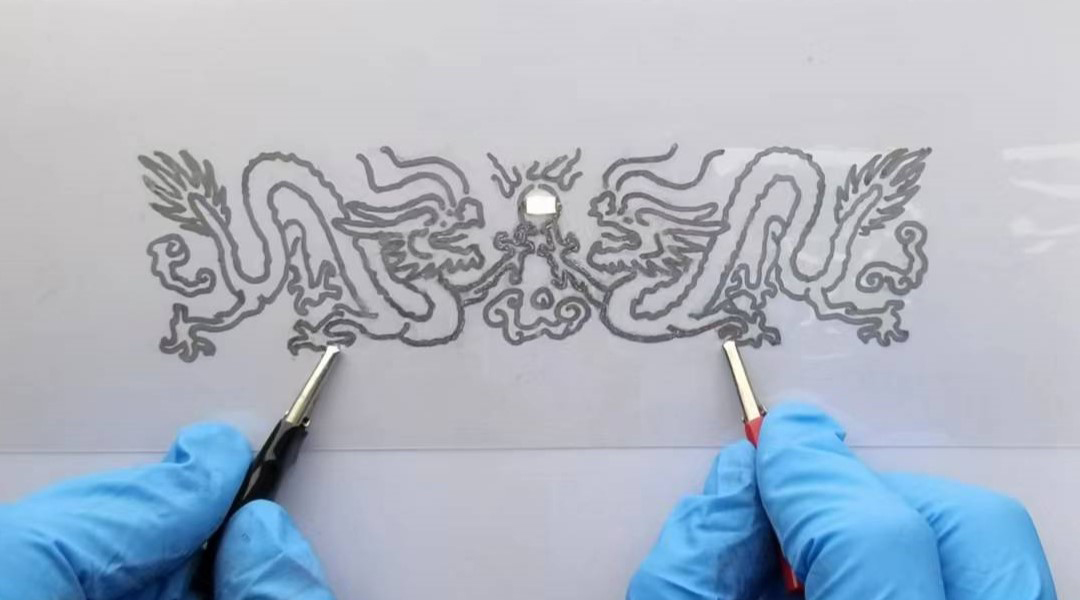

Because the spheres are nano-sized (ca. 100–250 nm), the material remained suspended in a liquid. To make a circuit, the researchers simply put their “metal ink” in a ballpoint pen and drew. They experimented with a dozen surfaces, including paper, wood, metal, and glass; the lignin adhered well to most surfaces.

However, on the nano-scale, the line they drew was not conductive because it was composed of individual lignin-shelled spheres, and the lignin shell blocked current flow between them. To solve this problem and complete the circuit, they used a roller to flatten the lignin-coated EGaIn beads. The roller crushed the lignin coating, releasing the EGaIn and allowing it to flow into a single line, while the lignin re-formed as a layer coating the tube, like the plastic coating on a solid metal wire.

The circuit was conductive, and if electricity was applied it would light an LED. Even better, it remained conductive even when bent or twisted. Sharp bends (radius 5 mm) increased the circuit’s resistance to the flow of electricity, but twisting, even at 720°, had no effect on the circuit’s resistance.

Recyclable circuits

Gallium is relatively rare, so recovery is important. Again, lignin’s properties make it a good choice for encapsulation because “lignin can be dissolved and recovered by adjusting the pH environment,” said Dai.

Sonicating the lignin-coated EGaIn beads in a basic solution dissolved the lignin coating, releasing the EGaIn, which aggregated back into a ball. Recyclability of the EGaIn was surprisingly efficient; after ten rounds of adding and removing the lignin coating, ~97% of the EGaIn remained.

Michael Dickey, who studies new ways to pattern soft materials at North Carolina State University and who was not involved in the study commented: “This work shows how lignin — an abundant and inexpensive material found in plants — can assemble as a coating on the surface of liquid metal particles. The coating helps stabilize the particles and allows them to be printed to form flexible and stretchable conductors. Such conductors can enable new types of soft and stretchable electronic devices.”

Metal and wood are simple, timeless materials, but here they are being combined in novel, nano-scale ways to produce futuristic devices. Lignin-coated EGaIn circuits have a myriad potential applications, including wearable sensors, biomedical devices, and transient electronics.

Dai and Si say that they “plan to further explore the unique combination of woody biomass and liquid metal to develop more functional materials”.

Reference: Lin Dai, Chuanling Si, et al., Lignin-Based Encapsulation of Liquid Metal Particles for Flexible and High-Efficiently Recyclable Electronics, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202310653