Hybrid processes and materials made of fiber-reinforced plastic (FRP) and metal for the automotive lightweight construction of tomorrow are the focus of the LEIKA research project. LEIKA stands for “Leichtbau in Karosseriebauteilen” or lightweight construction in auto body components. The objective of the research project is to decrease the structural mass in electric vehicles by using innovative hybrid materials with a focus on processes ready for large-scale series production.

“The new lab system at the Institute for Lightweight Engineering and Polymer Technology allows us to form and back-inject FRP-metal hybrid materials in one step. The resulting process and structure quality, together with the achieved cycle times of significantly less than two minutes, supports the potential of such hybridization on both the material and production end,” says Martin Würtele, Director of Injection Molding Technology Development at KraussMaffei.

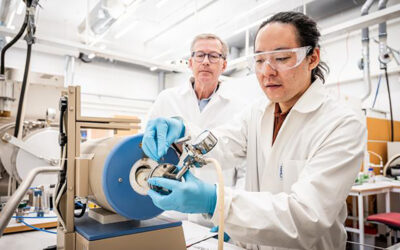

For the center tunnel of the floor assembly, the scientists combined metallic outer layers of steel with a core of CFRP. The result is a 25% reduction in mass. Photo: Dresden University of Technology/ILK

The new lab system is suited both for the manufacturing of components by injection molding and for the back injection of semifinished products. Furthermore, plastics can be used for compression in the mold or reinforcement for local areas in the component. This process sequence is implemented through the integration of a flat sheet die as well as a conveyor belt with an insertion robot. “The new test system lets us project a large number of incredibly varied processes on a single system. This lets us offer significant added value to our partners from the automotive industry,” says Dr. Michael Krahl, Project Manager and person in charge of LEIKA at the Institute for Lightweight Engineering and Polymer Technology.

Flexibility is also a subject of major interest in the implementation of individual system components. This is why KraussMaffei designed a bolt-on unit of reduced height which is completely integrated with the production line including a press, infrared oven, robot and conveyor belt. The unit is capable of both injection molding and extrusion, portioning the injection volume in the process. As stated in the requirements specifications, up to five areas can be reinforced locally in one cycle.

Using the floor structure for electric vehicles as an example, the partners demonstrated the suitability of real-world implementation in series production for innovative hybrid materials and their processes. For the center tunnel, the scientists combined metallic outer layers of steel with a core of controlled free radical polymerization (CFRP). “The first test results are excellent. The mass is reduced by 25% compared to an all-metal lightweight construction solution. Simultaneously, it was possible to demonstrate comparable performance under the most important load conditions with regard to stiffness and crash situations for components with significantly lower mass,” explains Würtele.