Food and pharmaceutical products traded across the globe must fulfill strict quality criteria. However, potentially harmful products still appear on the market, raising serious public health concerns. Such products are either manufactured in substandard quality – a typical feature of counterfeit products – or undesired properties develop during inappropriate storage. In an era of globalized trade relations where food and pharmaceutical products cross borders effortlessly, consumers face counterfeit and deteriorated products at elevated rates.

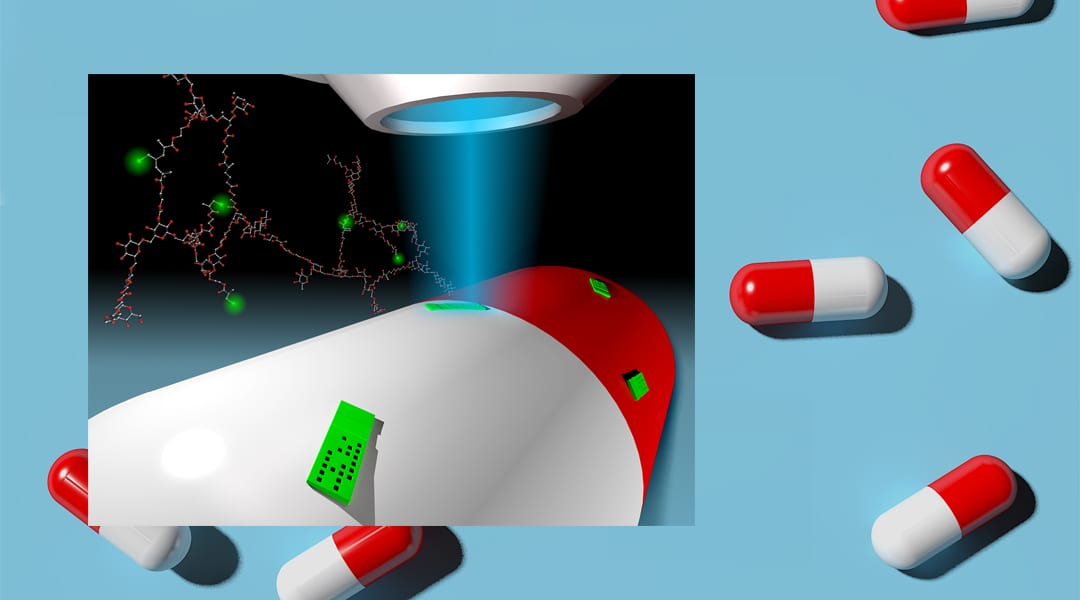

Multi-functional, biodegradable hydrogel microparticles that provide information on the authenticity and the potential deterioration of a tagged food or pharmaceutical formulation directly prior to consumption/use is presented in recent research published in Small.

The authenticity information is embedded in the microparticle topography as a binary code. The product safety of liquid products– the presence of the pathogens and the potential product deterioration due to improper storage – is reported through the sensors embedded in the microparticle structure.

The authenticity code and the sensor information are acquired with a standard bright-field/fluorescent microscope (or even a mobile phone in the case of authenticity). Incorporation of the sensors into the microparticle itself offers an all-in-one solution with potentially broader applications than the previously proposed alternatives placed on the packages.

The microparticle production is scalable, and it is a difficult technology to counterfeit, requiring advanced equipment and skills. The natural degradation of the microparticles and the ability to be directly placed on the products limits possibilities for unauthorized manipulation, repackaging, reprocessing and dilution of original products, which is a common practice in counterfeiting.

The proposed multifunctional system is orthogonal to other available methods; therefore; it brings an additional layer of security, recommended in the WHO strategy to fight counterfeiting. The multifunctional microparticles represent an integrated approach combining a microfluidic/lithographic technique that sculptures the microscale shape with molecular level chemical design enabling sensory and biodegradability functionality to protect consumers from potentially harmful counterfeit and deteriorated products.

Kindly contributed by the Authors, and edited by Jodie Haigh.