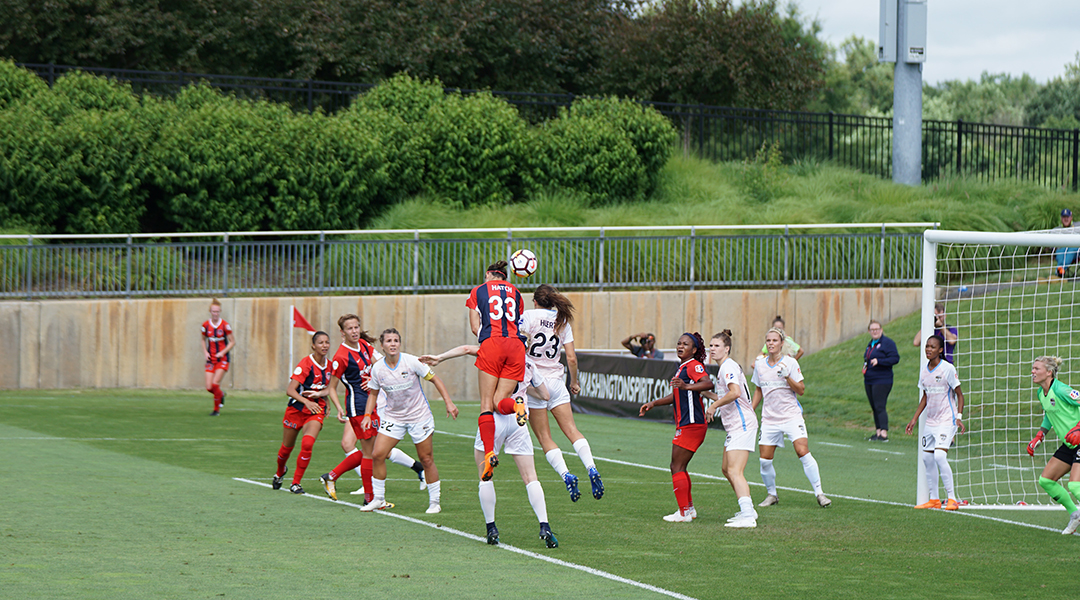

A combination of polymer nanofibers and zinc oxide nanowires have been used to make a highly sensitive impact sensor that could help gather safety data for sporting associations, like FIFA.

The link between head injury and neurodegenerative disease is well established. Even light blows from activities like heading a soccer ball can contribute to long term brain damage, which highlights the need for precise data about the impacts from sports.

Engineers at the University of Edinburgh recently published their design for a wearable impact sensor in the journal Macromolecular Materials and Engineering. The device is comprised of materials that have the unique ability to produce an electric charge when impacted or bent, even lightly, allowing the scientists to gather this vital information.

These materials are called piezoelectric materials and they are often used to power wearable and implantable technologies. Lead containing ceramics are some of the most efficient piezoelectrics but they have drawbacks, such as being too brittle and toxic, making them unsuitable for wearable tech.

Polymers, which are materials made from large chains of repeating molecules like carbon or peptides, are a promising replacement. Polymers don’t conduct as much electricity, but they are non-toxic, organic, and flexible and show promise in this area.

The group from Edinburgh built upon a piezoelectric energy harvesting material developed for shoes by one their colleagues. It is made of polymer nanofibers spun into a mesh which ends up looking like a bit of tissue. However, to work as sensor in the context of minor head trauma, the scientists would need to increase the charge it produced with each impact.

Increased surface area, increased charge

Michael Chung completed his Ph.D. at the University of Edinburgh, during which he saw the potential of the nanofiber electric harvester. Because the charge is created by impact on the material, his plan to increase the sensitivity of the nanofiber polymer was to increase surface area. The more material available to receive the impact, the greater the charge, which can then be correlated back to the amount of force that created it.

Chung had read about zinc oxide (ZnO) and its ability to improve performance and voltage output of polymers. Adding ZnO, another piezoelectric material, would increase the surface area of charge-generating material. However, getting inorganic ZnO particles to efficiently integrate with the organic polymers is difficult. For this, he turned to an exciting material called polydopamine (PDA).

“It’s something that’s not fully understood,” said Chung, “it seems to just spontaneously coat anything and that makes it brilliant because you don’t need to pre-treat your surface.”

The PDA coating solved several problems as it provided a solid, homogenous anchor to attach the ZnO and improved the electron transfer efficiency between the organic polymer and inorganic ZnO. The sturdy anchoring of PDA further allowed Chung to not only place ZnO particles on the nanofibers, but to further grow those particles into wires.

“I noticed during the testing that if you attach the zinc oxide in its particle form onto the fibers and then do some impact testing, it’s not actually that different from just using the fibers themselves. Whereas once you grow them into wires, the output is much greater,” said Chung.

The result is a mesh of polymer nanofibers with many ZnO wires sticking out. Norbert Radacsi, the principal investigator for this work, uses the analogy of a Christmas tree, where the ZnO wires are like the pines coming off the branches. If you jump on a pile of Christmas trees, it will be fluffy because the pines can absorb the energy of the impact. “If it’s just an old tree without any pines, then you will probably hurt yourself because they don’t absorb energy,” said Radacsi.

Homemade solution meets FIFA standards

A reliable sensor requires the charge produced by a set amount of force to be consistent over time. To test this, Chung needed a device that could apply a consistent unit of force to the material.

Unfortunately, the lab did not have a device that would apply the forces equivalent to a soccer ball or other sporting in impacts. They only had equipment to test incredibly high forces exerted on wings or blades. Therefore, Chung built homemade devices using the lab’s 3D printer or wood, which produced the levels of force he was interested in.

Both the impromptu devices and material performed well in these simulations and he measured a consistent response when the polymer, ZnO mesh was struck.

To confirm what the ad-hoc testing equipment was telling him, Chung reached out to colleagues in Switzerland who perform impact testing for one of the world’s largest sporting associations: FIFA. Using their highly calibrated and standardized set-up, he confirmed the performance and accuracy of the sensor.

Scalable and low cost

Chung believes this proof of concept could be one component of an array of sensors that correlate impacts in sports with neurodegenerative diseases.

“You need to combine it with other sensors, like a sensor array, around your head because the impact on your head is just one part of the story,” he said. Thankfully, the methods and materials used are quite scalable. The polymers and ZnO are low cost and facilities exist that can spin a meter squared of the nanofiber mesh in just one hour. “Since these sensors were just, I think 10 by 10 millimeters sizes,” said Chung “you’re going to get a lot of sensors out of that meter squared.”

For a low-cost, researchers and sporting associations could then measure the number and force of impacts experienced by players and use this to better understand their risks.

Reference: Michael Chung, et al., Enhanced Piezoelectric Performance of Electrospun PVDF-TrFE by Polydopamine-Assisted Attachment of ZnO Nanowires for Impact Force Sensing, Macromolecular Materials and Engineering (2023). DOI: 10.1002/mame.202200520

Feature image credit: Jeffrey F Lin on Unsplash