Polymeric membranes are a low-cost and environmentally responsible way to separate carbon dioxide gas in a variety of processes, for example from nitrogen for carbon capture in combustion processes or from methane in natural gas purification.

Polymeric membranes are a low-cost and environmentally responsible way to separate carbon dioxide gas in a variety of processes, for example from nitrogen for carbon capture in combustion processes or from methane in natural gas purification.

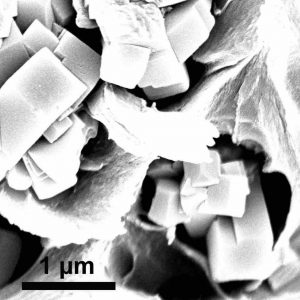

Often, fluorinated polyimides are used for these separations, because of their good selectivity for carbon dioxide. To enhance the performance of these polymers, composite membranes have long been investigated, often using zeolites to improve permeability. These composite membranes, however, are problematic, because the mixed polymer-inorganic matrix forms defects which in turn decrease the selectivity of the pure polymer for carbon dioxide.

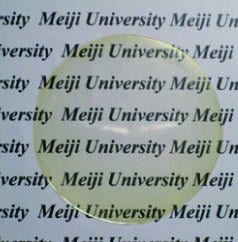

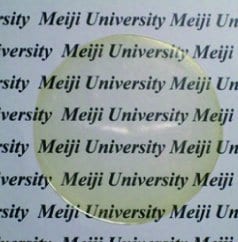

To circumvent this issue, compatibilizers or surface functionalization of the zeolites have been introduced in the past, though these solutions are not always optimal. Now, Kazuhiko Nagai and co-workers from Meiji University in Japan have shown, in a new paper in the Journal of Applied Polymer Science, that the simple introduction of a liquid, sulfolane, which is often used in industry for liquid-liquid extractions, is capable of improving the properties of the interface between the polyimide and the zeolite, and decreasing the density of defects.

To circumvent this issue, compatibilizers or surface functionalization of the zeolites have been introduced in the past, though these solutions are not always optimal. Now, Kazuhiko Nagai and co-workers from Meiji University in Japan have shown, in a new paper in the Journal of Applied Polymer Science, that the simple introduction of a liquid, sulfolane, which is often used in industry for liquid-liquid extractions, is capable of improving the properties of the interface between the polyimide and the zeolite, and decreasing the density of defects.

The reduction of defects in turn dramatically improves the selectivity of the membranes, over the composite polyimide/zeolite membranes without sulfolane, by a factor of two for carbon dioxide over nitrogen as well as methane. The composite membranes with sulfolane also have improved selectivity for carbon dioxide over hydrogen with respect to the pure polyimide membranes: this could provide important applications in integrated gasification combined cycle installations, or for the production of hydrogen with simultaneous carbon capture.