Solar energy technologies have progressed quickly since the bleak determinations of the remaining, readily accessible, global fossil fuel supplies as well as the desire to shift toward cleaner, renewable energy sources. Solar energy is a logical target as a renewable source, but the devices used to harvest light and convert it efficiently into a usable energy form tend to be very bulky and inflexible, and are therefore severely limited in how they can be applied.

A great deal of research is going into changing this, and the concept of flexible electronics has really taken off, at least in the research phase.

Groups collaborating across Germany and Qatar have now reported a way to fabricate thin-film light absorbers using an inkjet printer. The fact that inkjet printing is a well-developed technology increases the possibility of the quick application of such a fabrication process on a commercial or industrial scale, and makes it readily scalable by printing many thin-film devices in parallel. It also avoids the loss of excess materials spun off during spin-coating techniques.

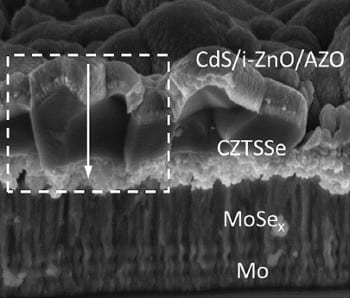

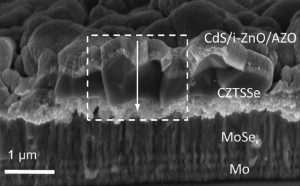

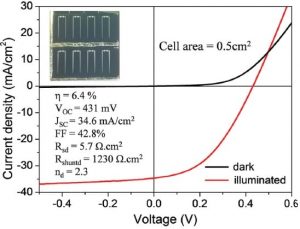

The researchers dissolve their ‘ink’ in a solvent stable enough for printing, print it onto a Mo-coated substrate, then anneal it to generate the composite Cu2ZnSn(S,Se)4. They report a power-conversion efficiency of 6.4% without an anti-reflection coating. While the current device performance is limited by its high series resistance, there is plenty of opportunity for improvement in such a flexible process.

The researchers dissolve their ‘ink’ in a solvent stable enough for printing, print it onto a Mo-coated substrate, then anneal it to generate the composite Cu2ZnSn(S,Se)4. They report a power-conversion efficiency of 6.4% without an anti-reflection coating. While the current device performance is limited by its high series resistance, there is plenty of opportunity for improvement in such a flexible process.

Advanced Science is a new journal from the team behind Advanced Materials, Advanced Functional Materials, and Small. The journal is fully Open Access and is free to read now at www.advancedscience.com.