The unrelenting miniaturization of transistors has led to increasingly numerous, dense, and robust interconnects that have enabled complex and powerful integrated circuits. While traditionally built using lead-tin eutectic solders, recent health and reliability issues have led to substantial research focused on new materials for semiconductor package interconnects. Though many of these new materials provide improvements over the incumbent eutectic, they often depend on costly deposition techniques and processes.

The unrelenting miniaturization of transistors has led to increasingly numerous, dense, and robust interconnects that have enabled complex and powerful integrated circuits. While traditionally built using lead-tin eutectic solders, recent health and reliability issues have led to substantial research focused on new materials for semiconductor package interconnects. Though many of these new materials provide improvements over the incumbent eutectic, they often depend on costly deposition techniques and processes.

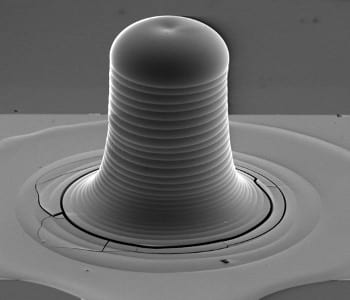

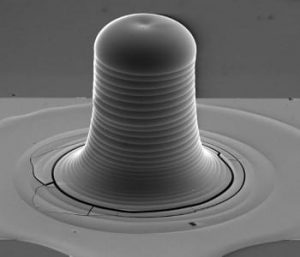

Now, new research has combined inkjet printing and metal nanoparticle inks as a novel, low-cost solution for interconnect fabrication. We describe a process for reliable 3D printing of these unique inks and demonstrate structures that outperform lead-tin eutectics while undergoing thermal curing treatments below accepted budgets. Not only does this process provide compatibility with current semiconductor processes, but it also provides a pathway for chip integration onto temperature-sensitive, flexible substrates expected to play a major role in the next generation of electronics.