Researchers in Korea transform electrohydrodynamic inkjet printing into a new 3D microfabrication technique.

The modern electronics industry relies on precision photolithography to constantly reduce the size of devices while increasing the density of micro components. However, it becomes very challenging to use photolithiography to fabricate complex designs beyond two-dimensional structures on flat surfaces.

While 3D printing appears to be an efficient recourse, most of the current techniques suffer from low resolution, rendering them useless for creating complex 3D microstructures. This has prompted Jang-Ung Park and colleagues at Ulsan National Institute of Science and Technology and Korea Institute of Machinery & Materials (both in Korea) to turn to

electrohydrodynamic inkjet (e-jet) printing that can achieve submicron resolution with 2D patterns.

In e-jet printing, external electric fields are applied to eject inkjets, in which the nozzles are not in contact with substrates. However, in order to successfully apply e-jet to 3D printing, the researchers had to solve the problem of ink wetting, a nuisance that prevents ink droplets from drying in time. They adjusted the geometry of the nozzles and apply a hydrophobic layer to the interior, so that with an optimized ink formula, ink droplets can be dried before reach the substrate, enabling the vertical stacking of ink materials.

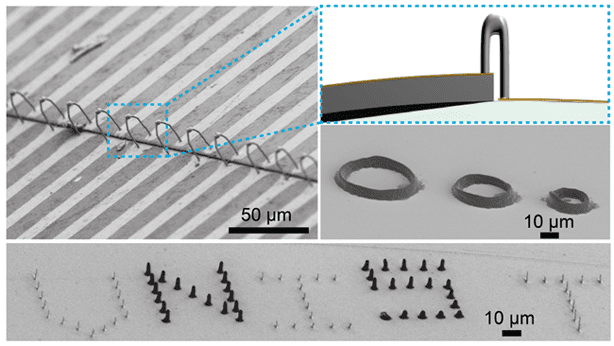

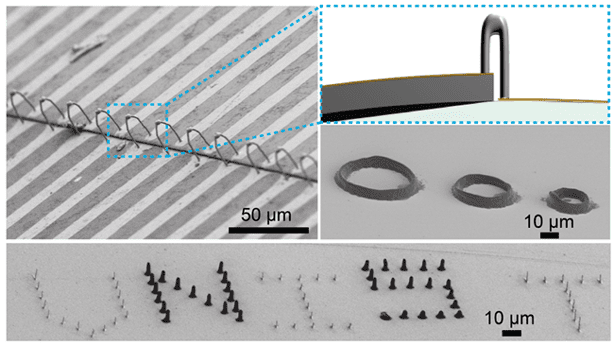

With this modified e-jet printing system, the team is able to print a wide range of fine 3D patterns with various ink materials, such as silver and copper nanoparticles or organic compounds. The patterns include vertical or helix-shaped pillars and straight or rounded walls, featuring aspect ratios as high as 50+ and diameters as small as 0.7 μm. They also demonstrate the printing of arch bridge-like freestanding silver interconnects on flexible plastic substrates, a feat that is hard to achieve using conventional integrated circuit packaging technologies. The authors note that “the resolution of e-jet is about 50 times better than commercial 3D printing systems, such as fused deposition modeling and filament-based direct ink writing.”

One reviewer deems this study as “a truly excellent work demonstrating the huge potential of e-jet printing to fabricate 3D complex multimaterial structures”. In order to make it practical for real fabrication applications, the authors look forward to improving the printing speed, possibly through “multiple-nozzle implementations of the 3D e-jet printheads, conceptually similar to those used in conventional ink-jet print heads”.