Nanostructured materials and strategies towards their synthesis are of increasing importance due to a growing demand for advanced materials e.g. for energy storage and conversion technologies.

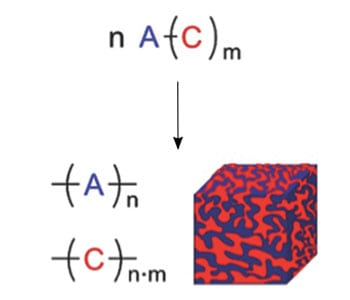

Classically, the two components of nanostructured hybrid materials can be formed successively or simultaneously. However, usually two reaction mechanisms are involved. In contrast, the twin polymerization describes the formation of two polymers starting from just one monomer in a mechanistically coupled process step. In this approach, hybrid materials with phase domains in the range of 0.5–2 nm are easily accessible, since the formation of two macromolecules takes place on the same time scale and phase separation is suppressed.

Monomers for twin polymerization usually consist of an organic and an inorganic building block combined in one molecule. These so-called twin monomers can be constructed using a set of established or novel building blocks.

To achieve multiphase hybrid materials, two or more twin monomers can be polymerized at the same time. This synthetic concept is called simultaneous twin polymerization and leads to a new classification of the occurring processes. It is theoretically possible to obtain four homopolymers, two homopolymers and one copolymer or two copolymers within just one process.

In the first review on the subject Thomas Ebert, Andreas Seifert and Stefan Spange (Universität Chemnitz) explain the principle of various twin polymerization processes and their appropriate terminologies. Different types of twin polymerization are classified with respect to the underlying processes and individual examples are highlighted, demonstrating their potential in material synthesis. A comparison with other scenarios for the synthesis of two different polymers within one procedure is also included.