One of the most damaging side effects of humanity’s reliance on fossil fuels, is the high frequency of oil spills at sea. To mitigate the environmental damage caused by events like deepwater horizon, a cheap, effective method of removing oil from seawater must be developed.

There is a large body of research on cleaning up oil spills. Two of the most prominent ideas are ‘skimming’ oil from the water’s surface, and the use of hydrophobic materials to absorb it. A recent paper in Advanced Sustainable Systems describes the applications of a brand new hydrophobic, absorbent material.

There are a number of important considerations that must be taken into account when designing such a material. It must have a high surface area, high buoyancy, be re-usable and its manufacture must be cost effective. With an eye to that last criterion, the research team’s Australian contingent, used the waste cooking oil from their university café for its manufacture.

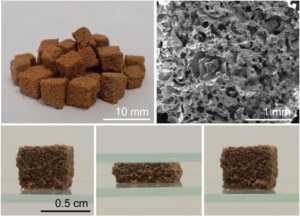

On a kilogram scale the waste cooking oil was heated and stirred in the presence of sulfur. This procedure generates a more viscous material through cross-linking the unsaturated components of the oil. Sodium chloride was then added to improve the material’s surface area to volume ratio. After cooling, the solid material had a brown, porous appearance

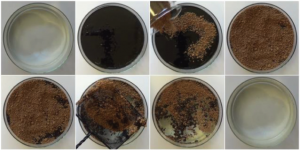

The substance showed excellent buoyancy, it absorbed only 56 mg of water per gram after soaking in water, and it was shown to very rapidly absorb oil. To demonstrate the material’s utility, 100 ml of crude oil was added to 1.5 L of seawater. The absorbent material was then added, and in less than one minute, removed from the water with a net. The rather impressive results can be seen in the image below.

After one cycle of use, the oil could be squeezed out of the absorbent material, and re-used. Given this invention’s cost effectiveness and utility, the authors are hopeful that it will rapidly find application in the clean up of aquatic environments.

The video and elements of the article were kindly provided by Justin Chalker.