An uniaxial press can assemble monodisperse silica spheres to photonic glasses that exhibit finely tunable Mie scattering. Currently, research on optical materials is significantly expanding toward disordered materials, thereby enabling the discovery as well as regulation of new optical phenomena. One particularly interesting approach to this topic is inspired by nature: the firefly’s lantern uses a reflector consisting of disordered monodisperse particles. Unfortunately, it has turned out to be a challenging task for scientists to obtain a completely random distribution of monodisperse colloidal particles without a perturbing supplement – until now.

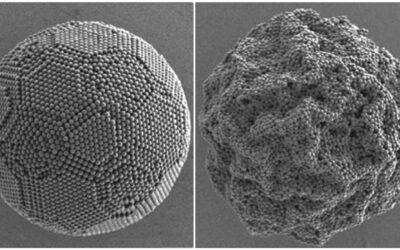

Cross-section SEM images of silica PGs (970 nm spheres) for different fabrication conditions.

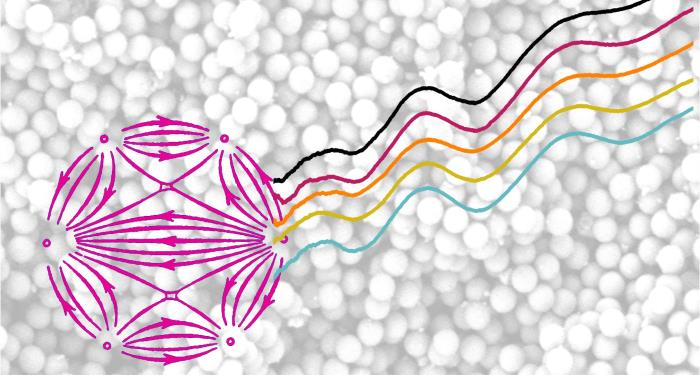

In a communication published in Particle, A. Blanco and co-workers from the Institutio de Ciencia de Materiales de Madrid describe a straightforward but efficient technique to obtain self-supported, <100 µm thick photonic glasses in minutes, instead of days, directly from particles of 200‑970 nm in diameter. The researchers use uniaxial pressure applied by a die to compact dry silica powder photonic glass pellets.

Using partially stabilized yttria tetragonal zirconia instead of steel as the die material turned out to be crucial for success, as was the case for the applied pressure: Too high pressure resulted in cracked spheres, as evident from scanning electron microscopy, while too low pressure prevented stable pellets, resulting in an optimal range between 160 and 480 MPa.

Optical characterization by diffusive optical transmittance spectra revealed a resonant behavior that was independent of the applied pressure. By comparing the glasses made from silica powder of various diameters, the scientists could derive a simple but powerful theoretical model identifying Mie scattering as the optical phenomenon responsible for the resonances. They were able to show a linear dependence of resonance on scatterer size.