The commonly accepted rational about graphene exfoliation is (roughly) that the more defects are introduced in the lattice, the more soluble are the sheets, the more efficient is the exfoliation. A recent paper published by Vincenzo Palermo and co-workers tackles this issue by comparing the different exfoliation routes of graphite to produce graphene by sonication in solvent, chemical oxidation and electrochemical oxidation.

The commonly accepted rational about graphene exfoliation is (roughly) that the more defects are introduced in the lattice, the more soluble are the sheets, the more efficient is the exfoliation. A recent paper published by Vincenzo Palermo and co-workers tackles this issue by comparing the different exfoliation routes of graphite to produce graphene by sonication in solvent, chemical oxidation and electrochemical oxidation.

Using an original approach, the authors analyse not only the graphene successfully dispersed in solution, but focus their attention on the graphite surface that is left behind after the exfoliation process.

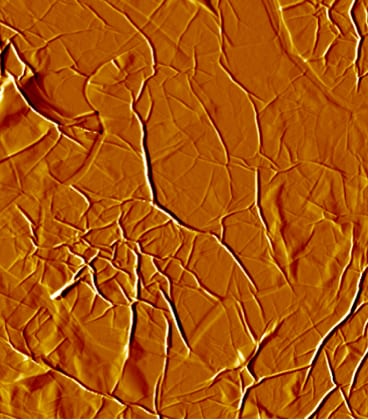

The exfoliation process and roughening of a flat graphite substrate is directly visualized at the nanoscale by scanning probe and electron microscopy. The etching damage in graphite and the properties of the exfoliated sheets are compared by Raman spectroscopy and X-ray diffraction analysis. The results show the trade-off between exfoliation speed on one side, and preservation of graphene quality on the other. A key step to achieve efficient exfoliation is to couple gas production and mechanical exfoliation on a macro-scale with non-covalent exfoliation and preservation of graphene properties on a molecular scale.