Light Rider has truly earned its name weighing a svelte 35 kg. With a 6 kW electric motor powering it from zero to 80 km per hour in just seconds and a frame boasting a mere 6 kg, the world’s first 3D-printed electric motorcycle is 30% lighter than conventionally manufactured e-motorcycles.

APWorks developed a lightweight motorcycle using bionic design and a selective 3D laser printing system. Source APWorks

3D-printing technologies have revolutionized the design and manufacturing process – not only in terms of structure and aesthetics, but also in impressive weight savings on parts and equipment when compared to those made using conventional manufacturing techniques.

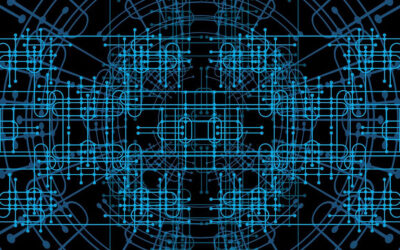

The algorithm used to develop the Light Rider’s optimized structure kept weight at a minimum while ensuring the motorcycle’s frame was strong enough to handle the weight loads and stresses of everyday driving scenarios. The result: a motorcycle that looks more like an organic exoskeleton than a machine. That was a very deliberate design goal for APWorks, a 100% subsidiary of Airbus Group, which programmed the algorithm to use bionic structures and natural growth processes and patterns as the basis for developing a strong but lightweight structure.

The Light Rider’s design echoes the form of a conventional motorcycle – but looks like a distant relative of today’s motorbikes. “The complex and branched hollow structure couldn’t have been produced using conventional production technologies such as milling or welding,” said Joachim Zettler, CEO of Airbus APWorks. “Advances in additive layer manufacturing have allowed us to realize the bionic design we envisioned for the motorcycle without having to make any major changes. With these technologies, the limitations facing conventional manufacturing disappear,” he added.

Each 3D-printed part of the Light Rider’s frame – produced using a selective 3D laser printing system that melts millions of aluminum alloy particles together – consists of thousands of thin layers just 60 microns thick. Leveraging the benefits of 3D-printing technology, APWorks designed frame parts that were hollow instead of solid, which has allowed for integrated cables, pipes and screw-on points in the finalized motorcycle structure – resulting in a dramatic 30% weight reduction over motorcycles produced using conventional manufacturing techniques.

“We further harnessed the benefits of metallic 3D printing by using our own proprietary material, Scalmalloy, for the construction of the frame,” said Zettler. Scalmalloy is a corrosion-resistant aluminum alloy that is virtually as strong as titanium. Specifically developed for ALM-based production, the material combines high strength with an extraordinary level of ductility, making it an especially interesting material to use for highly solicited parts in lightweight robotics, automotive and aerospace applications.