Detecting the smallest changes in magnetic fields is an incredible challenge, but it’s a critical task with big implications for everything from medical diagnostics to electric vehicle technology. Even tiny shifts in magnetic fields can reveal hidden issues — like early signs of deterioration in batteries — before they cause serious damage.

Now, researchers have developed a new type of quantum sensor that can measure these subtle changes with extraordinary precision. By harnessing the principles of quantum mechanics, these sensors could revolutionize fields like medicine, energy, and materials science.

What are diamond quantum sensors?

Among the most promising of these are sensors based on nitrogen-vacancy centers found in diamonds. Nitrogen vacancies are, as their name implies, a vacancy in the crystal structures created aside a nitrogen atom replacing a carbon atom in diamond’s otherwise carbon-based lattice.

“The diamond-based quantum sensors have advantages in wide dynamic range, high sensitivity, and a wide range of applications,” said Mutsuko Hatano of the Institute of Science Tokyo, the study’s lead author, in an email.

The interaction between the added nitrogen atom and the surrounding carbon lattice creates unique quantum states for the electrons around the vacancy. The sensitivity of these states to magnetic fields is what makes the centers exceptional magnetic field sensors.

When illuminated with green laser light, the centers emit red fluorescence, the intensity of which changes depending on the magnetic field’s strength. By measuring the brightness of this red light, the magnetic field’s strength can be determined with remarkable precision.

Producing quantum sensors on larger scales

Despite their potential, scaling up the production of diamond quantum sensors for commercial use has been difficult due to high costs and manufacturing complexities.

Additionally, natural diamonds, while available, are often prohibitively expensive and lack the ideal chemical impurity for such applications. High-quality sensors are typically manufactured by depositing carbon atoms onto a diamond substrate, layer by layer, using a gas decomposed into atoms by microwaves. This process produces a perfectly ordered crystal lattice necessary for a precise sensor but it is time consuming and — you guessed it — expensive.

To reduce the cost and complexity of producing diamond sensors, Hatano and her team devised a specialized diamond growth process. In this method, diamond layers are deposited onto a non-diamond substrate, which significantly lowers production expenses.

At a specific stage of diamond formation, when a highly regular crystal lattice had developed, nitrogen was introduced into the gas mixture. This nitrogen interacted with the diamond lattice, creating well-aligned and uniformly distributed nitrogen vacancy centers, as confirmed through detailed microscopic analysis.

Monitoring electric vehicle battery currents

Their exceptional sensitivity to magnetic fields, combined with the efficient new production method developed by the team, makes these sensors ideal for monitoring electric currents in electric vehicle batteries, contributing significantly to the advancement of clean energy solutions.

As current flows from a battery, it generates a magnetic field. Minimizing measurement error from the real current level can maximize the battery’s reliability.

The team tested their sensors by constructing a setup that replicated a real electric vehicle engine and placing the sensors inside to monitor deviations in the magnetic field from precise values, which could lead to battery overcharging/overdischarging or other issues affecting its performance and longevity.

The results were impressive, as they can be fabricated within the cost of wafer-scale mass production process comparable to other sensors. They were able to detect even the smallest fluctuations in the current, enabling the identification of any deviations from the optimal power usage of the system.

Next step, real-world tests

While the laboratory tests yielded exceptional results, the researchers acknowledge that real-world conditions will present additional challenges.

“We are planning in a few years to make a field test of the diamond quantum sensors while actually driving an electric vehicle,” Hatano said. “Large noise in a practical field environment may limit the sensitivity and accuracy of the quantum sensor. However, this will be overcome by enhancement of the sensor signal intensity, which can be achieved by electron beam irradiation into the diamond sensor, which should increase the number of nitrogen-vacancy centers, and improvement of the fluorescence collection efficiency by improving optics.”

Reference: Mutsuko Hatano et al, Heteroepitaxial (111) Diamond Quantum Sensors with Preferentially Aligned Nitrogen-Vacancy Centers for an Electric Vehicle Battery Monitor, Advanced Quantum Technologies (2025). DOI: 10.1002/qute.202400400

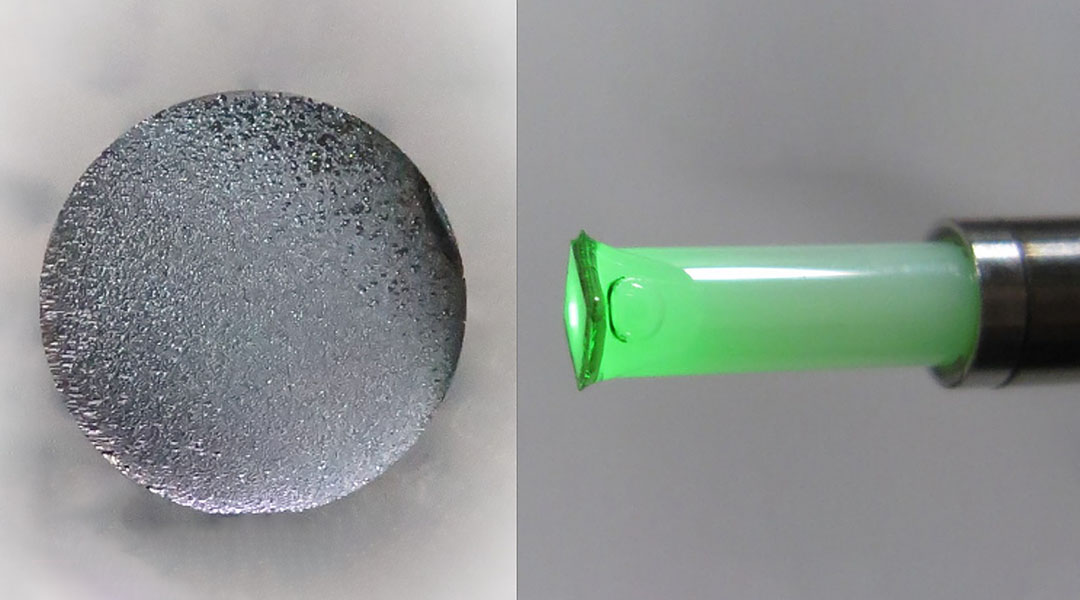

Feature image: Left: Top view of the heteroepitaxial diamond substrate with a diameter of 11.3 mm. Right: Diamond quantum sensor attached on the fiber top. Credit: Mutsuko Hatano et al.