Machine learning is becoming ever-more ubiquitous in our pursuit to solve the scientific problems of the day. From protein folding to image editing, machine learning is a well-established tool for making new discoveries.

One such area which would benefit from materials discovery is battery technology. Machine learning has been applied to predict the performance of rechargeable batteries, but was limited in the size of the data set and the model being unsupervised. And other challenges remain.

Now, in a recently published article in Macromolecular Rapid Communications, researchers at Waseda University, Tokyo, in collaboration with Fujitsu, have used machine learning to find candidate polymer materials for Li+ batteries much more efficiently.

“AI can predict new material structures with preferable parameters,” said Kan Hatakeyama-Sato, researcher at the Department of Applied Chemistry at Waseda University, and first author of the paper. “However, most candidate structures are known to be junk. They do not satisfy criteria for practical applications, such as synthetic easiness, stability, and processability.”

The authors argue that using AI alone to evaluate candidate materials is difficult because the AI doesn’t have the tacit knowledge that experts have in terms of what are preferable parameters for the material to have.

AI with expert help

Hatakeyama-Sato and the team looked at certain limitations to automating the process of discovering new battery materials and thought how they could be overcome with a little bit of expert help.

“Instead of teaching each exploration criteria of materials to AI,” said Hatakeyama-Sato, “the system was trained to learn what practical materials look like. AI learned their essential features by inputting the molecular structures of existing materials (unsupervised machine learning). Inspired by the existing species, our system could create unprecedented material structures with superior performances. This process is somewhat like designing new materials by expert researchers, using the broad experience of materials [that they have].”

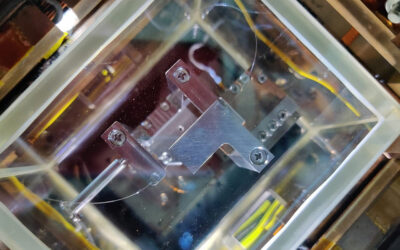

Once the machine has come up with its list of material candidates, these were explored using a new piece of hardware called a digital annealer, a powerful computing system that allows researchers to efficiently explore the candidate materials for suitability as battery materials.

“The AI system designed a new ion-conducting polymer,” said Hatakeyama-Sato. “The material offered good conductivity while maintaining the standards of solid-state electrolytes, such as chemical stability, thermal stability, mechanical robustness, and appropriate solubility.”

Future challenges for machine learning

Materials science would benefit massively from more efficient and sophisticated automation of the structure design process, particularly for organic materials. The researchers believe their system brings us a step closer to this goal. A next step could be that AI will tell us not just the ideal end-product materials, but the synthetic routes required to make them.

“Organic materials are difficult to design computationally because of their complex structures,” concluded Hatakeyama-Sato. “However, as these results demonstrate, new algorithms and hardware are gradually making pathways to the fully automated material design.”

Reference: Kan Hatakeyama-Sato et al., ‘Automated Design of Li+-Conducting Polymer by Quantum-Inspired Annealing‘, Macromolecular Rapid Communications (2022) DOI: 10.1002/marc.202200385

Image credit: Tyler Lastovich on Unsplash