Smart, programmable materials that can alter their shape and function on demand are highly desirable for applications ranging from robotics and wearable electronics, to architecture, manufacturing, and transportation. A wide range of novel materials have been developed in recent years, however, to date there is no single material system that can integrate effective, multifunctional shape manipulations.

Now, a team of researchers from the Georgia Institute of Technology and Ohio State University has developed a soft polymer material that changes shape based on the application of a magnetic field, which the team predicts could enable a range of new technologies.

According to the authors, the challenge in developing a versatile, programmable material is that some shape manipulations are contradictory to each other. For example, fast reversibility requires rapid shape transformation by actuation, but locking demands strong resistance to actuation.

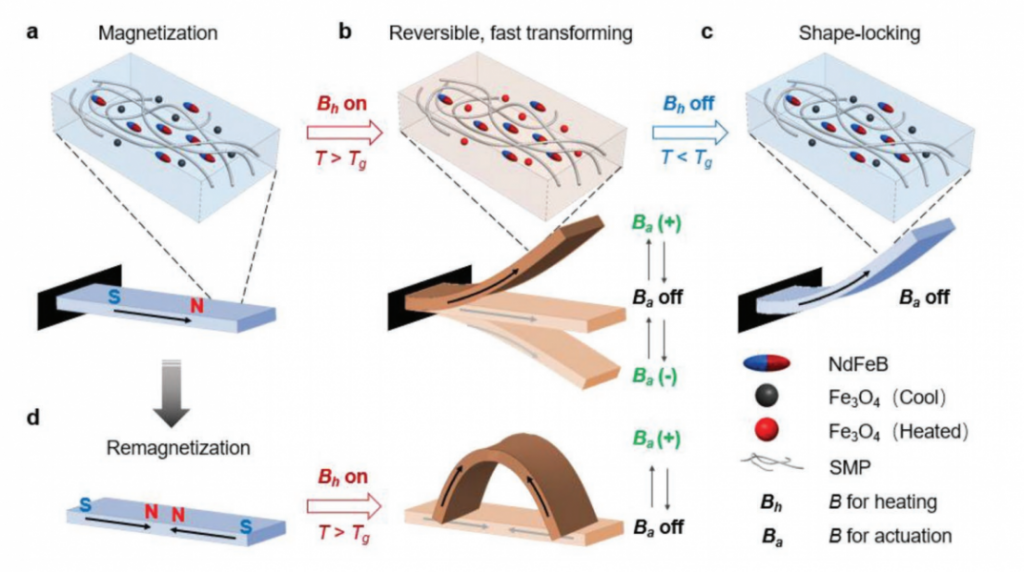

To overcome these challenges, a two component material was developed. The first component, an acrylate-based amorphous shape memory polymer (SMP), displays a low Young’s modulus, high stretchability, and a mild glass transition temperature (Tg, the temperature region above which a polymer transforms from ‘glass-like’ to ‘rubber-like’). These features mean the SMP becomes soft and malleable at a relatively low temperature, allowing actuation with little force, and without breaking. The second component, two types magnetic particles— Fe3O4 and NdFeB—give the SMP magnetic responsivity.

When a magnetic field is applied, the inductive heating of the magnetic particles causes the SMP to warm above its Tg, resulting in a soft and flexible ‘unlocked’ material with controlled bending properties. Once the magnetic field is switched off, the material cools below its Tg, it becomes rigid or ‘locked’, a process that only takes a few seconds.

The material properties can be adjusted by varying the ratios of both the polymers and the magnetic particles, allowing for a variety of customizable functions such as coiling and bending, and even the gripping of objects 1000 times its own weight.

This reprogrammable and unthethered system with fast reversible shape transformation and shape locking capability could be applied for energy-efficient operations in areas such as biomedical devices for minimally invasive surgery, active meta-materials, reconfigurable and flexible electronics, morphological computing, or autonomous soft robots, to name a few.