Mobile health (mHealth) devices are slowly but steadily substituting the bulky stationary hospital machines necessary for monitoring vital signs. Small wearable devices for personalized diagnostics, such as fitness-/activity trackers, are already available on the market. Such gadgets are designed for checking specific body functions, with 24-hour monitoring being most insightful, yet difficult to realize.

Body temperature, heart rate, respiration rate, and blood pressure are the four main vital signs routinely measured by medical professionals, yet the needs of individuals often vary related to the activities performed. Hence, modularity and customizability are key but often neglected in current research of medical monitoring applications.

To tackle this challenge, our lab has developed modular mobile and user-friendly devices using magnetic connectors, allowing wearable mHealth devices to be customized in a plug-and-play manner. Research for stretchable, wearable medical monitoring is currently restricted to devices pre-designed in the lab without the possibility for users (i.e., the patients) to make modifications and adjustments themselves.

With magnetic connectors, establishing mechanical and electrical connection between individual units is made easier than charging a smartphone. By simply detaching and reattaching magnetic units, users can exchange the power supply and sensors depending on their individual needs.

In this new technology, rigid magnets are embedded in a stretchable matrix with ultra-thin metal foils replacing the electronic part of the assembly. These imperceptible electrodes are fabricated by the wrinkling approach, where a rigid but ultra-thin metal foil is rendered stretchable by transferring it onto a pre-stretched elastomer. Subsequently letting that elastomer relax results in the metal foil on the surface of the elastomer to form wrinkles. This ultrathin electrode is thus stretchable up to the pre-strain applied to the elastomer in the fabrication process, as the wrinkles unfold along with applied strain.

To ensure long lifetimes and reliability of the wearable electronic devices, a fail-safe mechanism is implemented that prevents electrodes from rupturing. The magnetic connectors are designed to open before reaching the maximum strain that the electrodes can endure. Without this fail-safe, electrodes would easily rupture during everyday use. The operating principle of the fail-safe mechanism is the tuning of the strain at which the magnetic holding force is balanced out by the tensile force caused by mechanical load. Once the tensile force exceeds the magnetic force, the connection opens. To prevent electrode failure, this opening strain is tuned such that the connection opens at a strain considerably lower than the strain at which they would break.

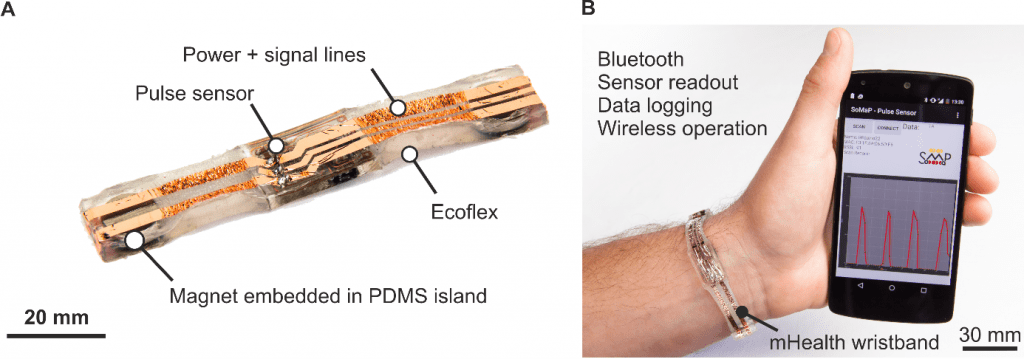

A fully functional and autonomous pulse sensor wristband demonstrates the ease at which modules with different tasks, i.e., sensor modules, power supply, and data transmission, can be assembled using this magnetic connector approach. Modules can easily be exchanged with no additional connections necessary, except the “snap-on” of the magnetic connectors, as they provide both a mechanical as well as an electrical link.

Such devices are thus designed to withstand the, at times, high operational demands that are unavoidable for wearables used in a patient’s daily life. These connectors are able to operate for more than 10,000 connect and disconnect cycles, meeting the standard for USB-C connectors found in consumer electronics.

Written by: Martin Kaltenbrunner and Doris Danninger

Reference: Gerald Kettlgruber, et al. ‘Stretch‐Safe: Magnetic Connectors for Modular Stretchable Electronics.’ Advanced Intelligent Systems (2020). DOI: 10.1002/aisy.202000065