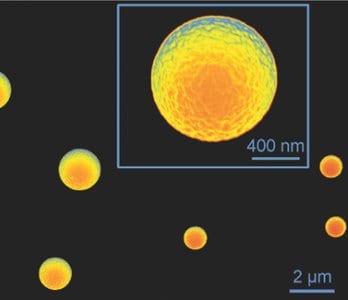

Silicones are one of the world’s most important and widely used polymers. They are highly biocompatible, and chemically resistant, stable to high temperatures, and repel water. Silicone polymers are found in everything from bathtub caulk to medical catheters and are even an approved additive to foods. Of the silicone family, polydimethylsiloxane (PDMS) is the most commonly employed. Making well-defined PDMS spheres, smaller than the diameter of a human hair (≈1 μm diameter), however, has proved nearly impossible, mainly due to the high viscosity and low surface energy of PDMS oligomers. However, such nano- and micro- materials are likely to create novel technologies and new applications in a number of scientific disciplines, e.g. in sensors, actuators, and additives for polymer resins.

Silicones are one of the world’s most important and widely used polymers. They are highly biocompatible, and chemically resistant, stable to high temperatures, and repel water. Silicone polymers are found in everything from bathtub caulk to medical catheters and are even an approved additive to foods. Of the silicone family, polydimethylsiloxane (PDMS) is the most commonly employed. Making well-defined PDMS spheres, smaller than the diameter of a human hair (≈1 μm diameter), however, has proved nearly impossible, mainly due to the high viscosity and low surface energy of PDMS oligomers. However, such nano- and micro- materials are likely to create novel technologies and new applications in a number of scientific disciplines, e.g. in sensors, actuators, and additives for polymer resins.

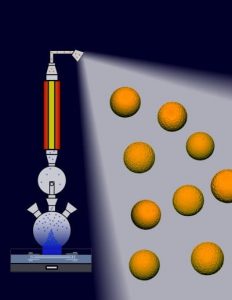

In their recent publication in Advanced Science, Kenneth S. Suslick and co-workers (University of Illinois, USA) present an extremely versatile, simple, and scalable process to produce silicone microspheres. They used this ultrasonic aerosol process to make microspheres with various properties, including some that are colored, fluorescent or magnetic. With this new method, silicone microspheres can be easily and readily synthesized, facilitating the exploration of technologies that have only been speculated upon so far. Read the whole research article now in the latest issue of Advanced Science.

Advanced Science is a new journal from the team behind Advanced Materials, Advanced Functional Materials, and Small. The journal is fully Open Access and is free to read now at www.advancedscience.com.