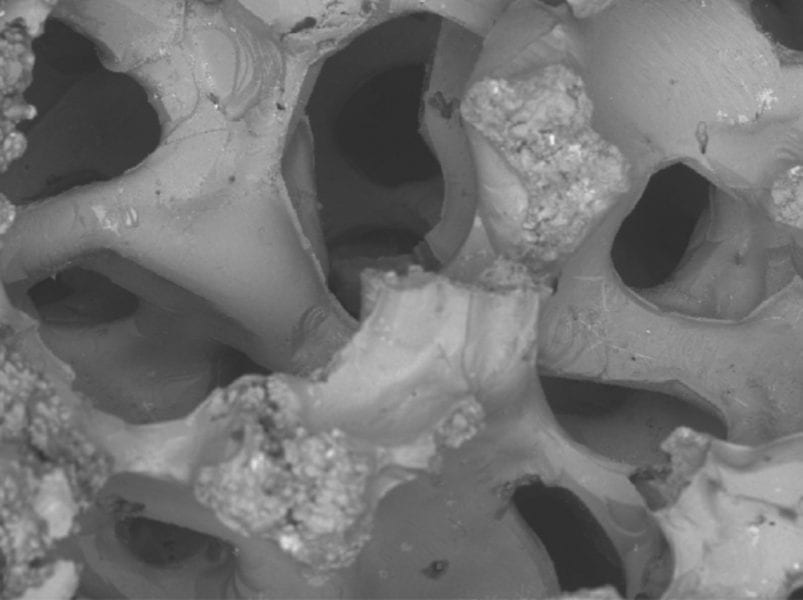

This magnesium “sponge” is a combination of one of the lightest metals and a structure made up of cells. The cells can be open or closed, of irregular or variable shape. Due to its structure, magnesium “sponge” can also be called porous magnesium or magnesium foam. The combination of the material and the structure results in a very good ratio of product weight to its strength. The properties of the magnesium sponge depend on the fabrication methods, relative density, porosity, pore size and pore connection. The hope associated with magnesium foams is mostly attributed to their use in implants, because of their biocompatibility and strength similar to structures in the human body. Because of their vibration-damping capacity property, it is possible to use magnesium foams as energy absorbers, for example in car crash-boxes. It is also expected that magnesium “sponges” could replace aluminum ones in some of their other non-medical applications.

Almost all of the porous magnesium manufacturing methods have been applied to aluminum foams before. However, they have been modified to work with the high reactivity and flammability of magnesium at the high temperatures required in fabrication processes. Various combinations of protective gases, foaming substances and space holding media are used to gain a wide range of porosities and foam structures.

Over the past several years, there has been a lot of publications about porous magnesium. An intercollegiate team of researchers from Wrocław University of Science and Technology and Helmholtz Zentrum Geesthacht summarizes in their review in Advanced Engineering Materials the current state of the research area with descriptions of the various fabrication methods and properties of magnesium “sponges”. Additionally, they describe corrosion resistance of magnesium foams and briefly review the differences between aluminum and magnesium foams made the same way.