It is well known that the mechanical properties of fiber-reinforced ceramic matrix composites are essentially determined by the fiber/matrix interface. Therefore, beneficial bridging of matrix cracks by fiber pull-out requires weak fiber-matrix bonding. The bonding strength can be properly controlled by deposition of a fiber coating prior to incorporation into the matrix. Ternary ceramics with a layered crystal structure, the so-called MAX-phases (Mn+1AXn with n = 1-3, M: early transition metal, A: A group element, X: C or N) exhibit high flexural strength and Young’s modulus, superior damage tolerance by delamination and kink-band formation, outstanding thermal shock behavior and oxidation resistance. Despite the fact that this remarkable combination of properties render the MAX-phases attractive materials for interfacial coatings in composites, the effects of the interphase on debonding and fiber sliding have remained largely unexplored.

It is well known that the mechanical properties of fiber-reinforced ceramic matrix composites are essentially determined by the fiber/matrix interface. Therefore, beneficial bridging of matrix cracks by fiber pull-out requires weak fiber-matrix bonding. The bonding strength can be properly controlled by deposition of a fiber coating prior to incorporation into the matrix. Ternary ceramics with a layered crystal structure, the so-called MAX-phases (Mn+1AXn with n = 1-3, M: early transition metal, A: A group element, X: C or N) exhibit high flexural strength and Young’s modulus, superior damage tolerance by delamination and kink-band formation, outstanding thermal shock behavior and oxidation resistance. Despite the fact that this remarkable combination of properties render the MAX-phases attractive materials for interfacial coatings in composites, the effects of the interphase on debonding and fiber sliding have remained largely unexplored.

At the chair of Glass and Ceramics at the University of Erlangen-Nuremberg researchers investigated the fracture behaviour of fiber reinforced ceramic composites with Ti3SiC2 fiber coatings. The uniform coatings were electrophoretically deposited on continuous SiC filaments and incorporated in a filler-loaded organometallic precursor matrix, which was subsequently converted into a Si-O-C based ceramic by thermal treatment. The polymer-derived ceramics route was selected as it is a cost-effective technique for the fabrication of ceramic composites.

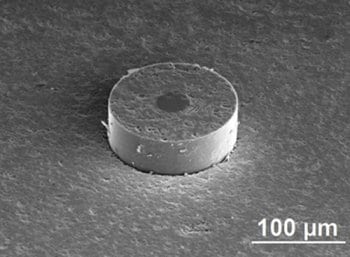

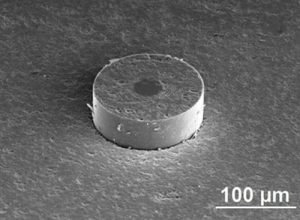

Microindentation studies and thermoelastic analysis revealed that the Ti3SiC2 coating thickness alters the thermal mismatch induced residual stresses at the fiber/matrix interface significantly. Consequently, the interfacial properties such as interface shear strength and sliding strength of composites with a Ti3SiC2 interlayer were enhanced. The study demonstrated that implementation of a thin Ti3SiC2 coating may offer a versatile route for the tailoring of fracture behaviour of fiber-reinforced polymer-derived ceramics.