3D printing initially emerged as a viable way for producing rapid, scaled prototypes of various parts. Though most commonly known for creating objects that can be seen or held, 3D printing technology has progressed so that structures can be fabricated on the micro-scale, opening a myriad of the possibilities in terms of structure design and materials to be implemented.

The microrobotics field has followed a similar progression. In the past 20 years, the research community has advanced from simply obtaining controllable movement of microscale objects to sophisticated microrobot designs that can autonomously deliver therapeutic drugs on-demand to target sites and manipulate tiny objects to precise locations for micro-manufacturing of the future.

One major challenge in the field of mobile microrobotics is the independent control of microrobots operating in teams and swarms to perform collaborative and parallel tasks, for either medical or micro-manufacturing applications. In order to be able to apply the appropriate controls to the individual, and typically identical microrobots, the microrobots must be easily identifiable and tracked in real-time using an imaging system, such as a camera.

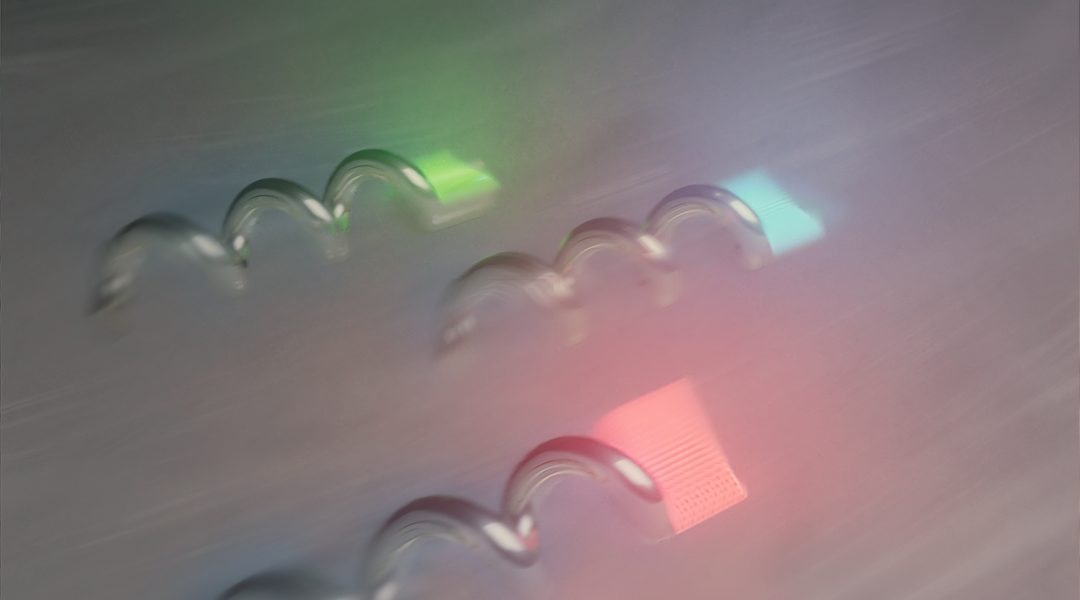

Using a micro-3D-printing technique called two-photon polymerization (TPP), detailed parts with sizes smaller than the diameter of a human hair can be made. In a recent study carried out by researchers in the Multi-Scale Robotics and Automation Lab at Purdue University, TPP was used for the first time to 3D print mobile microrobots with color-expressing features for microrobot identification and tracking. These features aren’t colors in the traditional sense but “structural colors”.

“Structural color occurs when visible light interacts with tiny patterned features that absorb and reflect light in different ways. The spacing, size, and shape of these tiny nanostructures trap light at a particular frequency producing an expression of a specific color,” said Cara Koepele, one of the lead researchers conducting the study. Another, Dr. Maria Guix, stated: “This is the same way that butterflies, beetles, and other insects found in nature express vivid colors.”

The team has demonstrated the ability to embed different and distinct color-expressing features in microrobotic systems for the first time using this flexible 3D printing fabrication technique, which shows great potential for mass production. Professor David J. Cappelleri, who directs the Multi-Scale Robotics and Automation Lab, said: “We are excited about these results and look forward to exploring this phenomenon in more detail in order to tune the color expression for not only microrobot identifying and tracking purposes but also for creating novel on-board sensing and anti-counterfeiting capabilities for 3D-printed microrobots.”

Reference: C. A. Koepele, et al. ‘3D‐Printed Microrobots with Integrated Structural Color for Identification and Tracking‘, Advanced Intelligent Systems (2020). DOI: doi.org/10.1002/aisy.201900147