In recent years, additive manufacturing (AM) has grown, and as a consequent the production and design of components has changed and continues to change dramatically. Subtractive manufacturing methods have limitations associated with the level of complexity that manufactured designs can attain, while in contrast AM enables endless creativity with the ability to produce complex geometries and architectures.

The AM of metals enables production of designs that include inherent properties that make them ideally suited for structural support, electrical conductivity and heat dissipation applications. Techniques such as selective laser melting and electron beam melting have played an important role in the commercialization of AM; however, the size resolution that can be achieved with such techniques is only in the macroscale range.

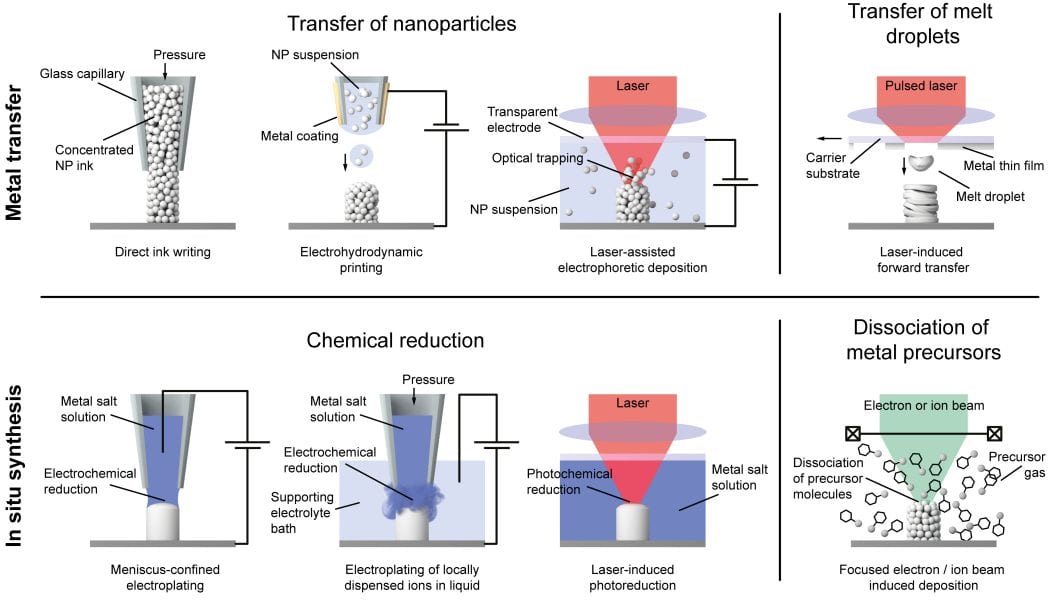

While research is ongoing in the optimization of a variety of techniques to enable micro- and submicro-meter scale metal AM, a recent comprehensive Progress Report by Tomaso Zambelli and co-workers looks to highlight some of the recent innovations in the field.