Silk is a natural polymer that exhibits biocompatibility, biodegradability, and customizable mechanical properties. The silk fibroin protein is naturally produced by several species of animals, including silkworms and spiders.

The extraction of silk from silkworm cocoons is one of the oldest techniques for textile fibers, and is the most thoroughly studied silk source for use in biomedical engineering application. Silk biomaterials are highly versatile and range from wound dressings and stitches to the tissue engineering of bone, cartilage, and ligaments.

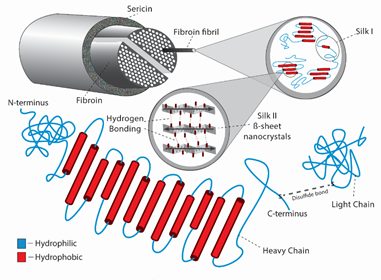

When extruded from the silkworm the fibroin fibers are “glued” together with another protein, sericin. When sericin and fibroin come in contact with the body they cause an immune response; this can be prevented by removing the sericin from the fibroin fibers prior to implantation. After the fibroin fibers have been isolated, the silk can be processed into a number of material formats, including films, nanoparticles, hydrogels, and sponges depending on the regenerative application.

The highly tunable mechanical and degradation properties of silk are greatly affected through the silk processing, due to structural changes caused by varying techniques and practices. There are two regions of the silk fiber, the light chain and the heavy chain, that have different characteristics and properties. The heavy chain is composed of highly repetitive amino acid sequences that bind together increasing the strength and organization of the fiber. Controlling the number of bonds allows the mechanical properties to be controlled. The higher the strength and toughness of the material, the longer it will last inside the body. This customizability allows silk to be used for many different tissue engineering applications.

Overall, silk is a promising biomaterial that is continuing to be investigated for its potential uses in biomedical applications and tissue engineering.

Read more in a review article in WIREs Nanomedicine and Nanobiotechnology.

Kindly contributed by the Author.