3D manipulation of cells and other biofunctional components into tissue‐like structures is needed for tissue engineering and drug testing. Additive manufacturing approaches like 3D bioprinting allow for application‐ and patient‐specific designs at high resolution and enable structural complexity. Normally, a bioink needs to be extruded and then rapidly stabilized to maintain a printed structure, requiring bioinks that are viscous and/or that transition into solids through an external cue (e.g., ions, temperature), but these properties and processes can compromise biomaterial viability.

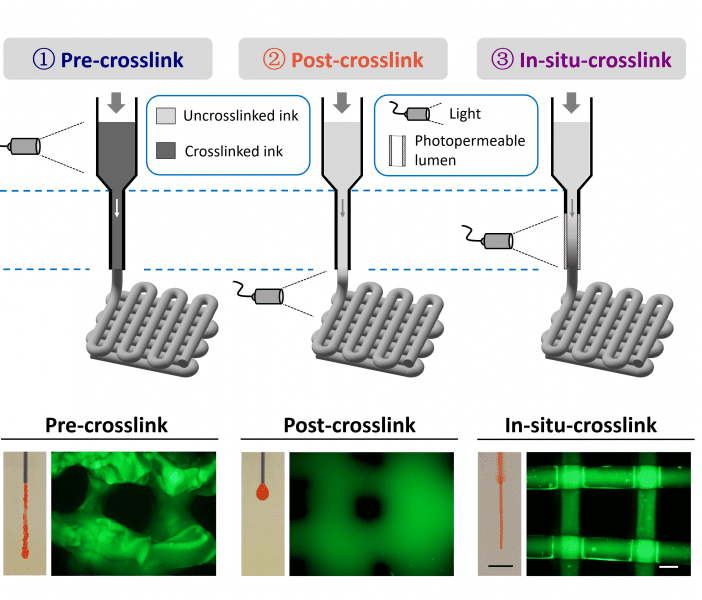

Photocrosslinkable hydrogels show promise in this regard but their application to bioprinting has thus far been hindered by their low initial viscosity and challenges in polymerizing the gels fast enough to maintain printed structures. Cross-linking prior to and post printing have disadvantages. Now, Jason Burdick and colleagues from the University of Pennsylvania, USA, and Tsinghua University, China report in Advanced Materials a general method for 3D bioprinting of photocrosslinkable hydrogels without limitations on ink viscosity (see Figure below).

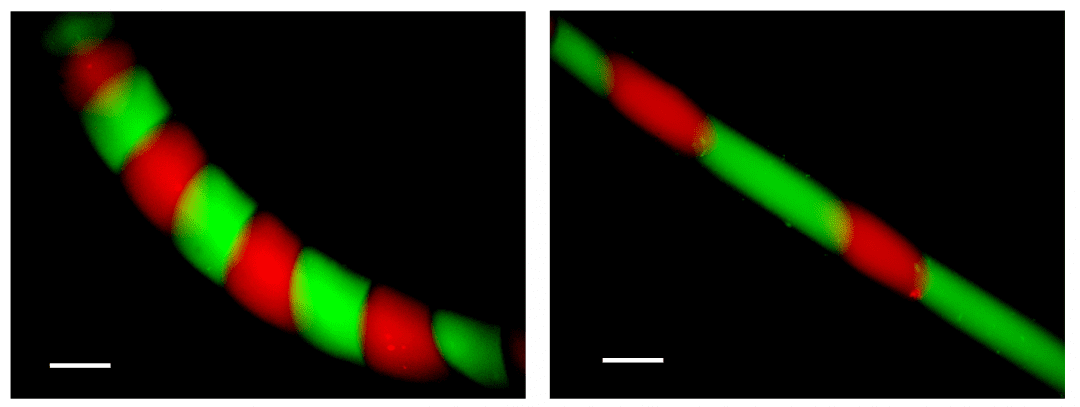

The researchers introduced a photopermeable capillary to simultaneously crosslink the bioink as it was being extruded though a coaxial nozzle immediately prior to deposition, a process they call in situ crosslinking. The method allows the printing of controlled, heterogeneous filaments that consist of core–shell structures, hollow tubes, and heterogeneous material compositions along the filament length. 3D structures like lattices, hollow tubes, and tissue constructs were produced with a range of synthetic and natural bioinks and with cross-linking using both ultraviolet and visible light. The hydrogels were printed with consistent filaments and high cell viability (>90%).

The advantages of this approach are that there is no viscosity modulation or copolymerization with other polymers, it can be generalized to various photocrosslinkable hydrogels, it permits the encapsulation of viable cells, and that it can be used to print heterogeneous and complex structures.