Biological structural materials such as nacre and bone have achieved superior mechanical properties as a result of well-designed microstructure. Among all the manufacturing methods to emulate design and assembly principles learned from the nature, freeze casting is a novel and promising way to form a variety of bioinspired structural materials with an excellent microstructural control.

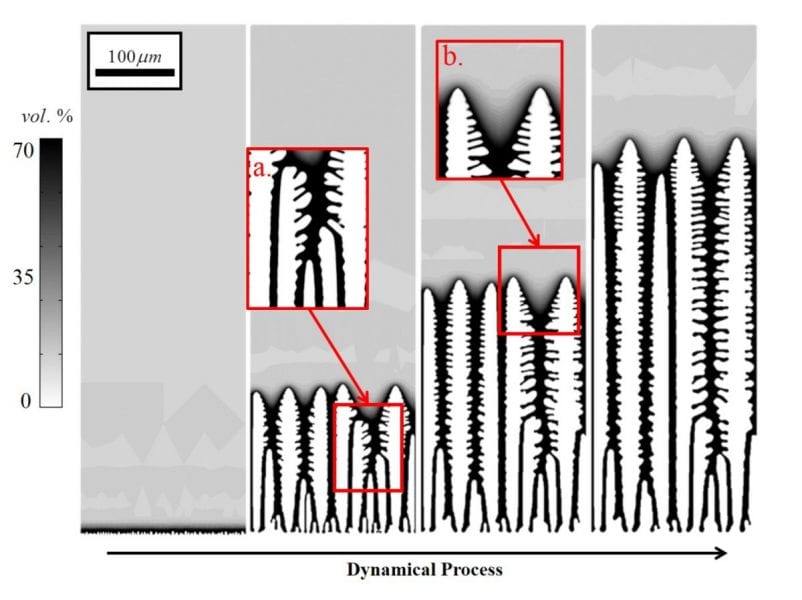

Freeze casting exploits the solidification behavior of a solvent to form controllably porous ceramics, metals or polymers. By freezing colloidal suspension, ice crystals nucleate on one side of the slurry and grow along with the external temperature gradient. The ice crystals redistribute the suspended particles as they grow within the slurry, effectively templating the desirable porous microstructure.

This paper by Chuin-Shan Chen et al. presents what is probably the first working phase field model of freezing colloidal suspension. Under the assumption that the colloidal particles can be represented by a concentration field, the interfacial condition of mass conservation, the Gibbs-Thomson condition, and particle segregation can be naturally included in the model. The proposed phase field model allows us to track the evolving interfaces during the solidification process and predict the dendritic and laminar microstructures often seen in freeze casting.

The simulated results not only agree well with experimental measurements, but also enables exploration of the influence of different processing variables on the evolving morphology of microstructures. As we now have the access to 3D evolving architectures through microCT, the proposed model opens a gateway to design next-generation bioinspired structural materials with freeze casting.