Metal-organic frameworks (MOFs), or more specifically “MOFilters” (MOF filters), may be the answer to a major global health issue; that is, anthropogenic air pollution from particulate matters (PMs).

In Advanced Materials, a group of researchers from the Beijing Institute of Technology, in China (one of the countries worst affected by PM air pollution) have developed a roll-to-roll hot-pressing method for the mass production of versatile MOF coatings for PM filtration.

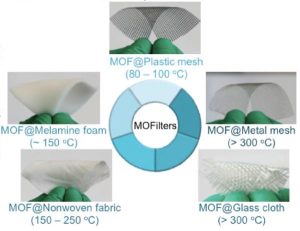

Five commercially available substrates that were used in this study with three different MOFs.

In their study, the researchers tested combinations of five commercially available, cheap, and flexible substrates (i.e., plastic mesh, glass cloth, metal mesh, nonwoven fabric, and melamine foam) with three different MOF types (i.e., Zeolite Imidazole Framework-8 (ZIF-8), ZIF-67, and Ni-ZIF-8) (see Figure). The MOFilters were synthesized by covering the desired substrate with the starting materials for the MOF of choice and then rolling this setup between two rollers using, for example, a rolling speed of 15 rpm at a temperature of 80 °C.

Overall, the MOFilters demonstrated excellent robustness over a temperature range of 80 to 300 °C, superior PM removal efficiency, at both room temperature (e.g., ZIF-8@Melamine foam, PM2.5: 99.5% ± 1.7%) and at 200 °C (e.g., ZIF-8@Glass cloth, PM2.5: 96.8% ± 1.3%), long term retention rate (>90% over a month), and reusability.

In future, the researchers envisage that these versatile MOFilters could be tailored to various domestic and industrial applications, such as pipe filtration, inlet barrier filtration for vehicle or aircraft engine systems, and baghouse dust collection.