Ever-increasing levels of CO2 emissions is one of greatest environmental concerns today, because of its potential effects on climate change, species extinction, and plant nutrition deterioration. Reduction of CO2 emissions is therefore top priority.

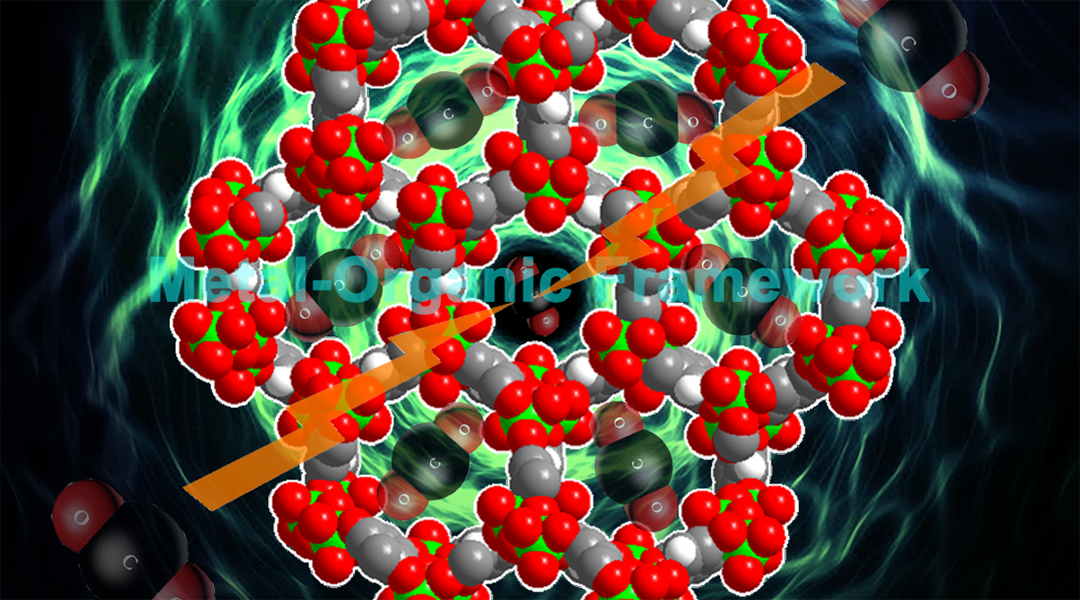

Metal–organic frameworks (MOFs) are a class of crystalline adsorbent materials that are believed to be one of the most promising next-generation technologies for carbon capture. MOFs show ultrahigh porosity, boundless chemical tunability, and surface functionality over traditional porous zeolites and activated carbon.

In industry, MOFs are required to be pelletized and packed into columns for CO2 capture. To meet industrial standards, MOF‐based CO2 capture – including the process design and engineering – needs to be evaluated.

As a step toward this, Dr. Zhigang Hu and coworkers from National University of Singapore evaluate the materials, process design, and performance of current CO2 capture technologies.

Four approaches for CO2 capture are outlined: post-combustion capture, direct air capture, pre-combustion capture, and oxyfuel combustion. Current techniques for evaluating the interaction strength between CO2 and MOF adsorbents are also discussed. Relevant aspects including the Clausius–Clapeyron equation, calculating ideal selectivity, calculating real working capacity and gas selectivity, obtaining gas diffusivities, and material stability under multiple‐cycle CO2 sorption tests are touched upon.

Dr. Hu and colleagues also evaluate MOFs from a multidimensional perspective: regeneration feasibility, ideal and practical gas separation performance, industrial evaluation energy consumption, and cyclic stability.

It is hoped that by evaluating the above-mentioned topics, along with increased collaboration between the MOF research and engineering communities, the gap between the chemistry and chemical engineering perspectives could be bridged, improving applications of MOFs as adsorbents for industry‐scale CO2 capture in future.