As the applications of nanotechnology grow more sophisticated, the controlled deposition of exceedingly thin layers of materials becomes of ever growing importance. A well-known technique called atomic layer deposition (ALD) can meet this challenge quite well for the deposition of thin inorganic oxide films.

As the applications of nanotechnology grow more sophisticated, the controlled deposition of exceedingly thin layers of materials becomes of ever growing importance. A well-known technique called atomic layer deposition (ALD) can meet this challenge quite well for the deposition of thin inorganic oxide films.

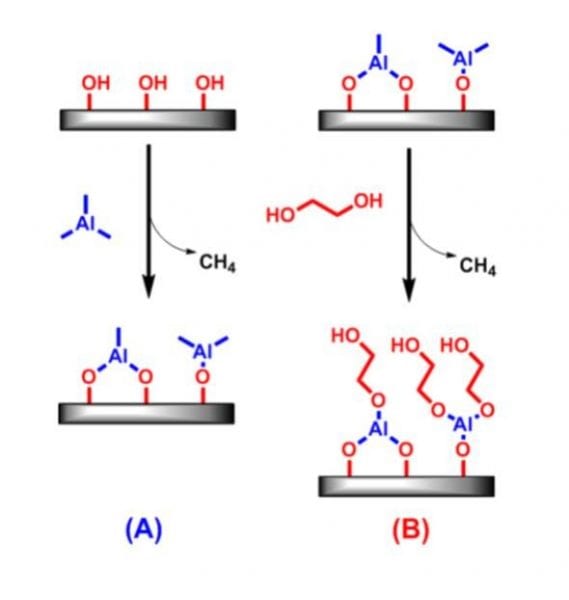

Using this method, films can be deposited one atomic layer at a time, as if meticulously built up by a nanometer-sized bricklayer. Each deposition step uses a metal-organic precursor, and the remaining organic ligands are subsequently burnt off leaving only the inorganic film as well as preparing the surface for the next deposition step.

In its traditional method of application, it would seem that there is no chance to incorporate organic components into such films with ALD. However, Professor Steven George and co-workers have written a short review on an emerging technique called Molecular Layer Deposition (MLD), where hybrid materials can be fabricated using an adaption of conventional ALD. This new method promises open up a whole new array of possibilities for surface scientists, by adding a new degree of flexibility to thin film preparation.

In its most common form, MLD can be used to make self-limiting, conformal, pinhole-free films of metal-organic materials called metalcones. The first example of this sort was the synthesis of “alucones” (aluminum-containing metalcones) from trimethylaluminum and ethylene glycol, as illustrated in the accompanying image above. Based upon this methodology, there is a great deal of flexibility for altering the metal as well as the organic ligand in order to fabricate hybrid thin films with customized properties. By mixing the precursors for oxide growth using ALD with those used for MLD, one can also tune the degree of incorporation of the organic component in the films.

Using this method, researchers have already tuned the elastic modulus of thin films for mechanical applications, the refractive index for optical applications, and the electrical conductivity for electronic applications. All of this means that one can tailor the properties of a surface coating “made to order”. The films can then be used as is, or the organic component can alternatively be burnt off to create a material with tailored porosity for applications such as catalysis. With such a degree of tunability, the possibilities are virtually endless, as Molecular Layer Deposition helps to change the face of nanomaterials, one layer at a time.